Using Video Analytics to Improve Critical Facility Security & Safety

The use of video surveillance in industrial settings is ever increasing. The convergence of inexpensive high-resolution video, high speed IP, and advanced computing and software technologies have made the benefits of adding video monitoring to critical industrial applications more accessible.

Video systems now aid in improving personnel and public safety, process and product quality, and site security. These benefits of a video monitoring system can be further enhanced by using video analytics.

Video analytics provide the capability to analyze a live or recorded scene from an IP video camera for a variety of potential threats. Analytics may be provided by supplementary software or may be an integrated feature of deployed cameras.

Video Analytic Software

Video analytic software is designed to work with your chosen VMS software. Most advanced VMS packages, such as those provided by IVC, provide APIs to easily integrate analytics-generated alarms into a comprehensive video monitoring system. This software can address one of the weak links in a video-based monitoring and security system: the operator. Since their software does not get tired, distracted, or bored, it reacts quickly to a variety of potential threats:

- Activity in critical areas

- Camera Tamper

- Line Crossing

- Wrong Way motion

- Intrusion

- Man down

- Personnel & asset tracking

- Left Object

- Object Taken

- Speeding

- Loitering Person

- Idle Vehicle

- Crowd Monitoring

- Over Capacity Detection

- Smoke and Fire

- Compound Events

With the proper VMS alarm management, alarms generated by these events can be used to initiate a variety of camera actions and VMS operations. For industrial applications, the VMS should also include support of protocols such as MODBUS and OPC so that analytic alarms can also be passed along to the process control system.

Camera-based Analytics

At the core of camera-based video analytics is greater image processing power in today’s high-definition cameras. Industrial cameras with integrated analytics provide for more targeted analysis where it is needed. Analytics at the edge is ideal for use at remote facilities that may have limited communication bandwidth. Camera-based analytics provide efective solutions without requiring additional servers.

4K cameras with advanced imaging processors and large memory arrays, are now available with integrated analytics. The high resolution of these cameras allow for extremely detailed analysis of the scene under scrutiny.

When mounted in a pan-tilt unit, these cameras can have the added capability of motion tracking. In industrial applications, this is an ideal safety feature that can be used for personnel and asset tracking as well as intruder tracking.

Use Case – Petrochemical Safety and Security

IVC worked with a major analytics software provider to integrate support of their video analytics with IVC’s Alarm Server. A component of iVC’s VMS, the Alarm Server listens for and detect alarms from the analytics software. Responses to the video analytics alarms can be tailored to fit the application using the IVC Alarm Manager. Possible response actions could include but are not limited to:

- Camera operations (moving, recording, etc.)

- Initiation of visual cues to operators, such as changing the view they are watching

- Initiation of audio cues to operators and other personnel

- Other commands to IVC’s camera management software

- HTTP commands to initiate commands to other connected devices or software

- Windows commands to initiate commands to other connected devices or software

Alarms generated by video analytics software are detected by IVC’s Alarm Server. Programmable alarm definitions in the Alarm Server determine alarm responses.

IVC has successfully implemented this integration for a major project at a large polyethylene plant built in Central America. An IVC camera system comprised of over 60 hazardous area cameras was procured for this project.

The primary purpose of the video system is for process and safety monitoring. However, because of the critical nature of the chemicals to be used and produced at the plant, site security is also of great concern.

Consequently, the customer desired to have a video system that included the advanced video analytics listed above. IVC worked with a major analytics software company to provide an integrated solution. Of particular interest for this customer were the following:

- Activity in critical areas

- Crossing of virtual trip wires

- Intrusion

- Object left behind

- Object taken

- Loitering

Advanced video analytics can be used to ensure compliance to regulatory requirements.

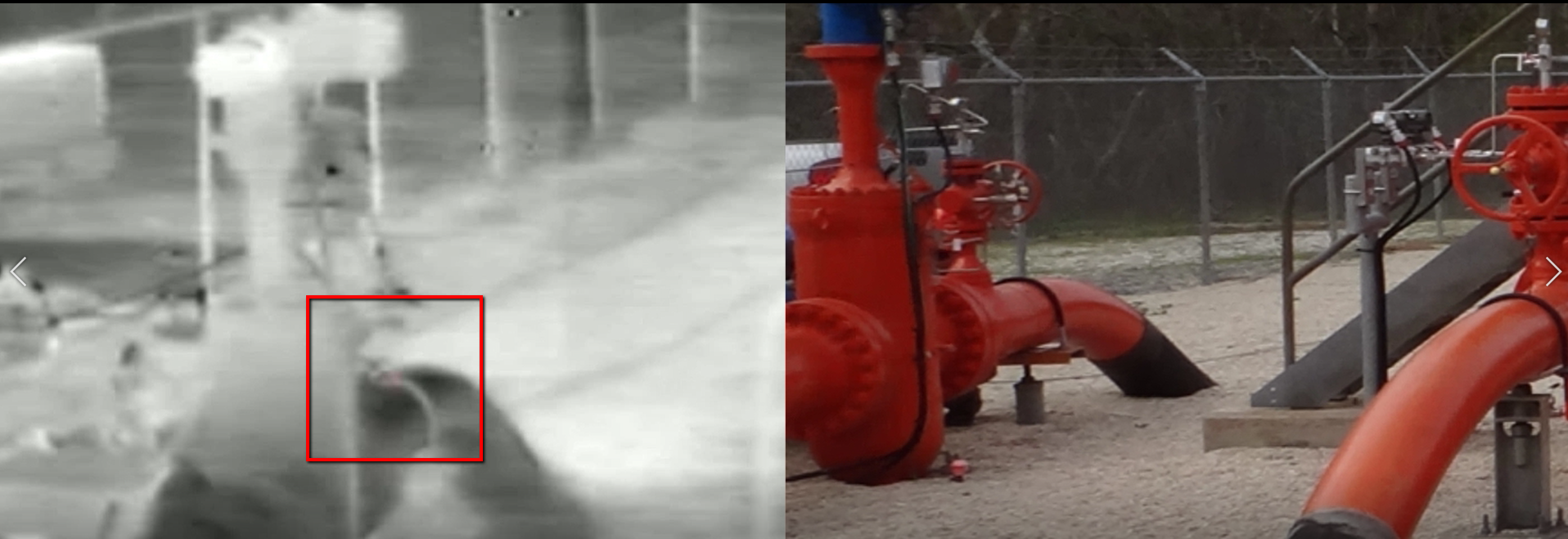

IVC cameras are placed around the perimeter of the facility and at key operational locations. Two of the cameras are specialized dual- imaging cameras that include one optical zoom module and one thermal module mounted on a precision pan-tilt unit. These cameras are configured to monitor the are stacks on site.

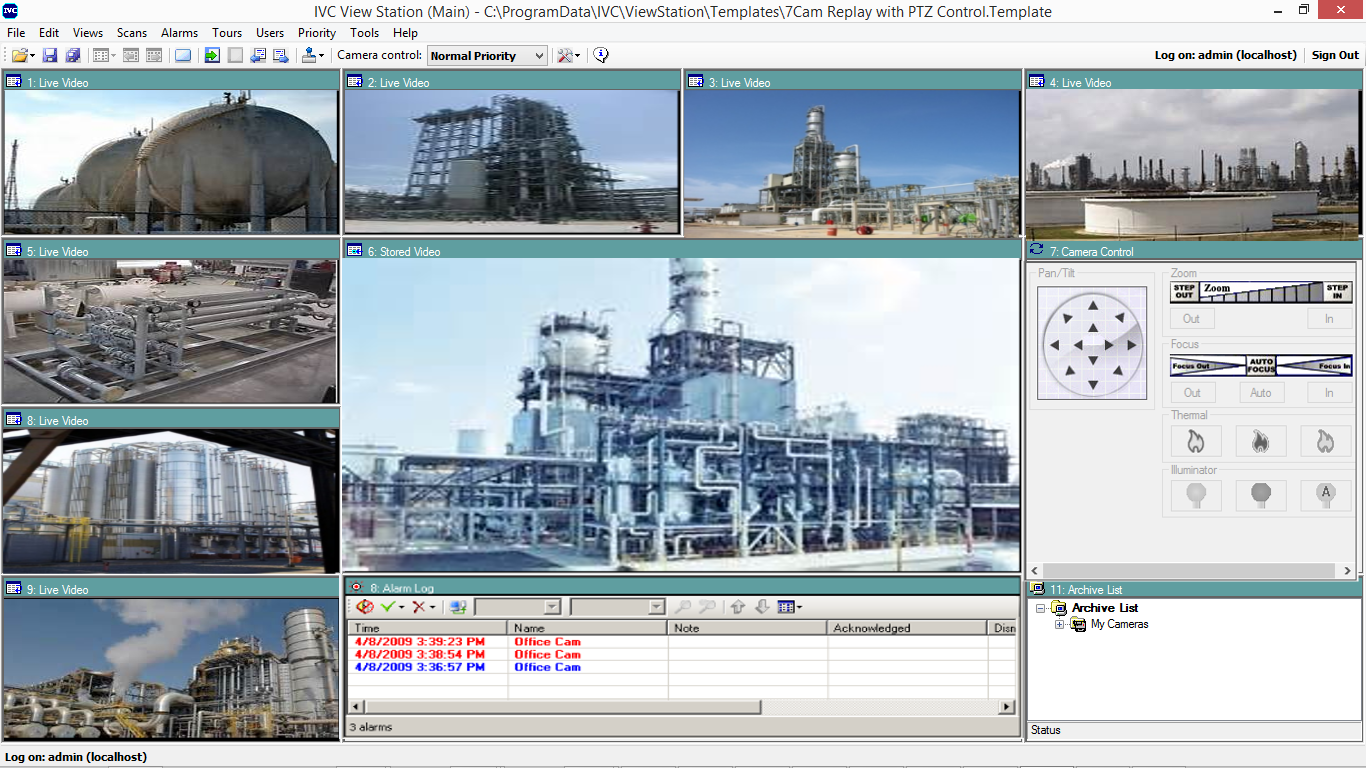

All live video streams from the cameras are sent to the IVC Relay Server. The Relay Server “relays” the video to all connected clients. In this system clients include workstations with web-browsers, workstations with IVC’s View Station software, and SCADA HMI screens that have been configured with video windows and camera controls. Additionally, live video from the Relay Server is also sent to servers running the video analytics software.

The analytic software is configured to monitor one or more of the items listed above for each camera. Should the analytic software detect an alarm condition, it sends an HTTP message to the IVC Alarm Server. The Alarm Server then parses the message to determine which alarm responses to initiate for the detected alarm(s).

Alarm responses are unique to each alarm defined in the IVC system. Responses could include:

- Move pan-tilt-zoom cameras to preset or specific position

- Increase resolution and/or frame rate on related cameras

- Record video on one or more cameras

- Change operator view on View Station workstation

- Initiate visual cue to operator on View Station

- Initiate audio cue on View Station computer

- Send emails to predetermined list with alarm-related video clip and data

- Send HTTP commands to connected devices or software (This can be used to activate PAGA systems, shut down systems or sub-systems, activate access control systems to restrict access or facilitate evacuation, etc.)

- Send Windows commands to other utilities on the computer hosting the Alarm Server.

- Initiate SNMP traps to indicate status on SNMP monitoring software

- Log the alarm for display in the IVC View Station Alarm Log

- Save alarms to database (for future analysis)

IVC’s View Station software provides an unlimited number of customizable operator views that may include Alarm Log listing alarm events initiated by video analytics software.

Benefits

Using video to analyze events in an industrial setting often means the labor intensive activity of reviewing hours or maybe days or more of recorded video. While this e effort is going on there is no certainty that the cause of the event has been adequately addressed. The convergence of high performance IP cameras, robust camera management software, and advanced video analytics software now makes it possible to analyze and react to events in near real-time.

Heightened security concerns at many industrial sites, such as this polyethylene plant, demand a more vigilant surveillance approach. IVC industrial video solutions coupled with video analytics software provide a security solution that is less dependent on constant monitoring by security personnel. Additionally, since location and type of alarm event are automatically determined and system reactions are tailored to each alarm, responses to events are quicker and more comprehensive.

The implementation described above is less dependent on human monitoring of live video. Since all video and related data are IP-based, rapid dispersal of event-related video clips and data to appropriate personnel, including first responders, is now possible. This ensures that any potential hazards to equipment, personnel, and the public are quickly addressed. Find out more on how security facility management can be improved.

For more industrial video solutions, check the IVC’s website.

Sorry, the comment form is closed at this time.

Logan Bell

Really interesting read. A full video solution involves not only the monitoring and storing of data, but being able to analyse it too. This is the way to ensure that systems are fit for purpose and protecting people and businesses.