Elevating Predictive Maintenance: The Transformative Impact of IIoT

In the bustling arena of the industrial landscape, the repercussions of unplanned downtime resonate deeply. According to a study by Aberdeen Research, unplanned downtime can cost a company as much as $260,000 an hour. Such challenges have been a persistent

Is predictive maintenance at a dead end?

Predictive maintenance has become a standard phrase in the equipment business and it is taking hold with OEMs. However, maintenance teams are not seeing much use for it. For them, “predictive maintenance is like chasing one’s own tail” – a

How to achieve Overall Equipment Effectiveness (OEE) using Real-time Maintenance (RtM)

What if your production equipment was always available as planned? What if your cycle time was never compromised because of a damaged machine? What if your production equipment self-detected and alerted you of quality defects? Applying Real-time Maintenance (RtM) technologies to your production

A Plant Asset Management Strategy Must Reflect the Next Normal Situation

The COVID-19 outbreak has accelerated a digital transformation (DX) in the manufacturing industry, notably in the area of enterprise asset management. With the emergence of Industry 4.0, maintenance has stepped out of the shadows. Organizations are accessing the newest technology

Pace-up with Your Fleets Through IoT Technology

The Internet of Things (IoT) is introducing automation to boost the productivity of every industry. The technology plays an important role by connecting the fleet assets with suitable applications to make the operations safer, greener, and cost-effective especially in the

How to Minimize Asset Failure with Predictive Maintenance

Existing maintenance solutions limit production. With the legacy tools and processes at their disposal, manufacturers commonly take reactive or scheduled maintenance approaches that present a multitude of challenges: Existing Maintenance approaches are costly: Up to $1.3M per hour cost of downtime in auto

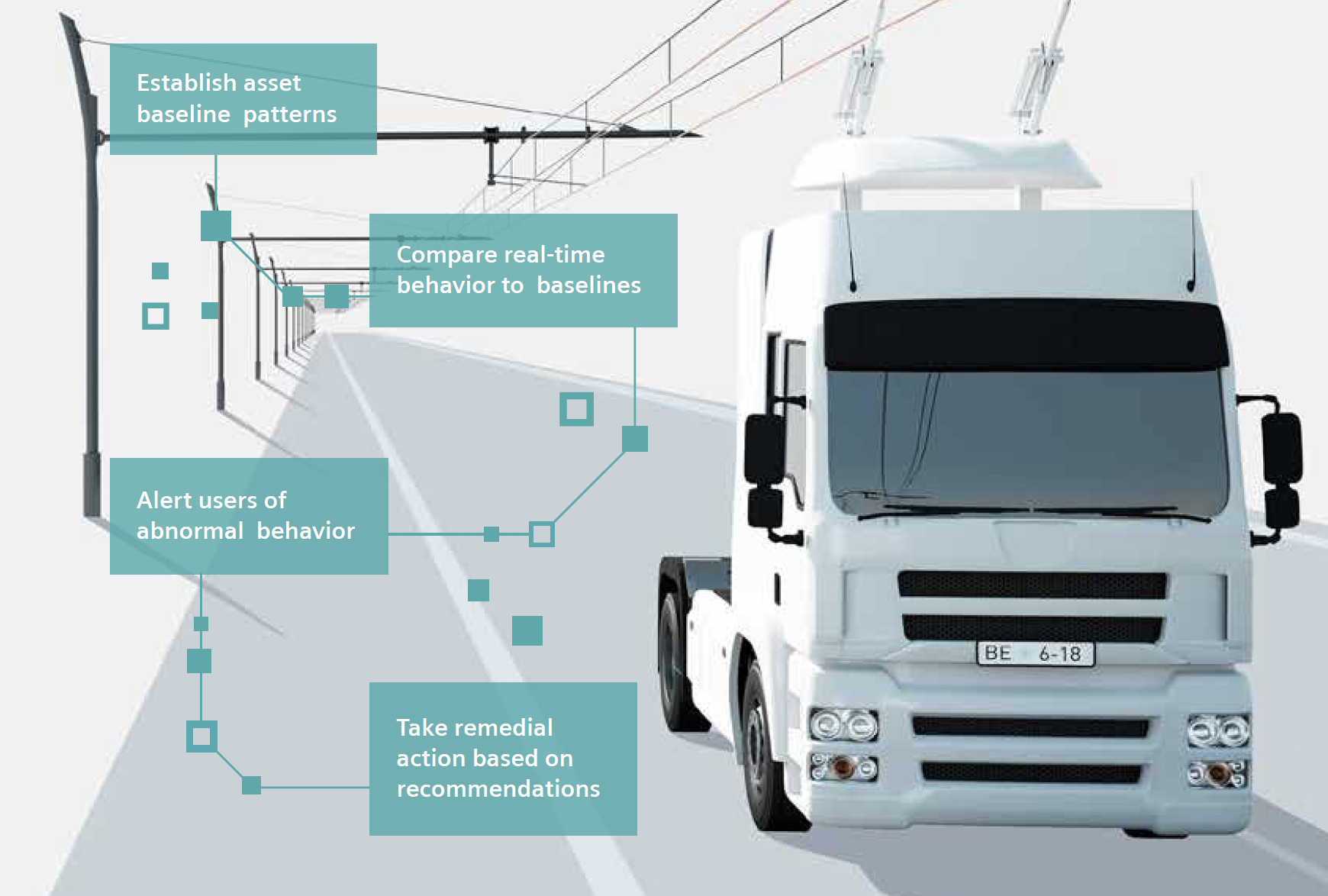

Six Steps to Predictive Maintenance

The manufacturing sector is facing a myriad of challenges, but they all point in one direction – improving the bottom-line performance. Within the energy sector, one of the most important drivers is to increase operational efficiency. Asset management is key

Data science in the hands of operations & maintenance teams

"Having spent, over a decade building machine learning and A.I solutions for E.ON we realized that there is clearly a gap in the technology currently on the market." TY Burridge-Oakland This gap is the real time machine learning analysis of multi-year

Maintaining Factory Efficiency in a Crisis through Remote Monitoring

The World Health Organization’s (WHO) announcement about Covid – 19 reaching pandemic levels triggered responses across the industrial world. In industrial manufacturing, shop floor activity hit its lowest levels since the Second World War and in many cases manufacturing facilities