How to Minimize Asset Failure with Predictive Maintenance | SPONSORED

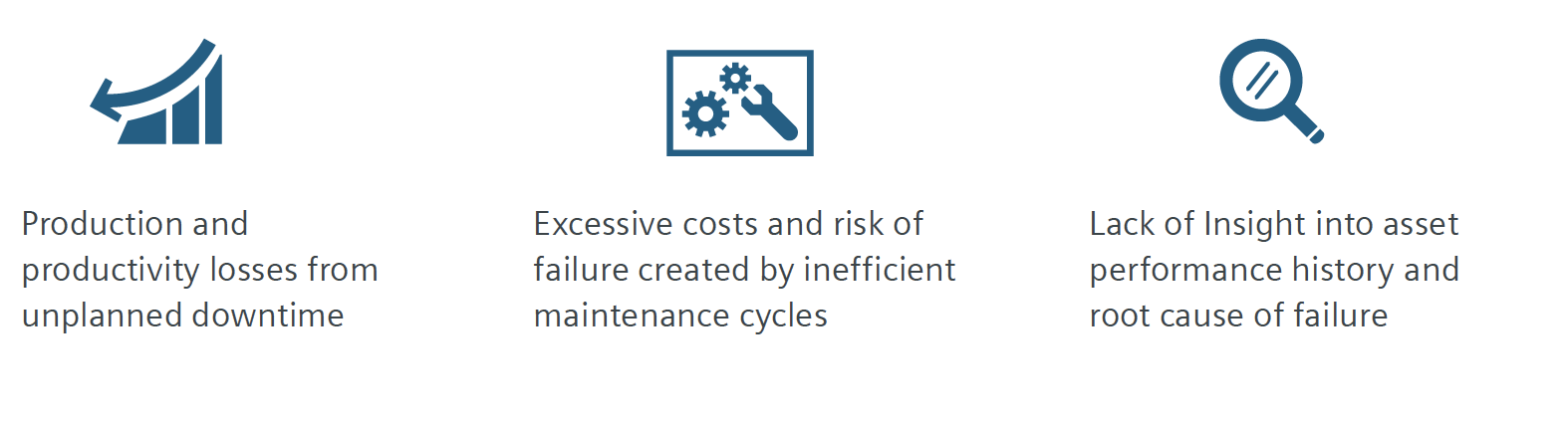

Existing maintenance solutions limit production. With the legacy tools and processes at their disposal, manufacturers commonly take reactive or scheduled maintenance approaches that present a multitude of challenges:

Existing Maintenance approaches are costly: Up to $1.3M per hour cost of downtime in auto manufacturing (Source: PTC)

10x cost of unplanned downtime compared to planned (Source: ARC Advisory Group).

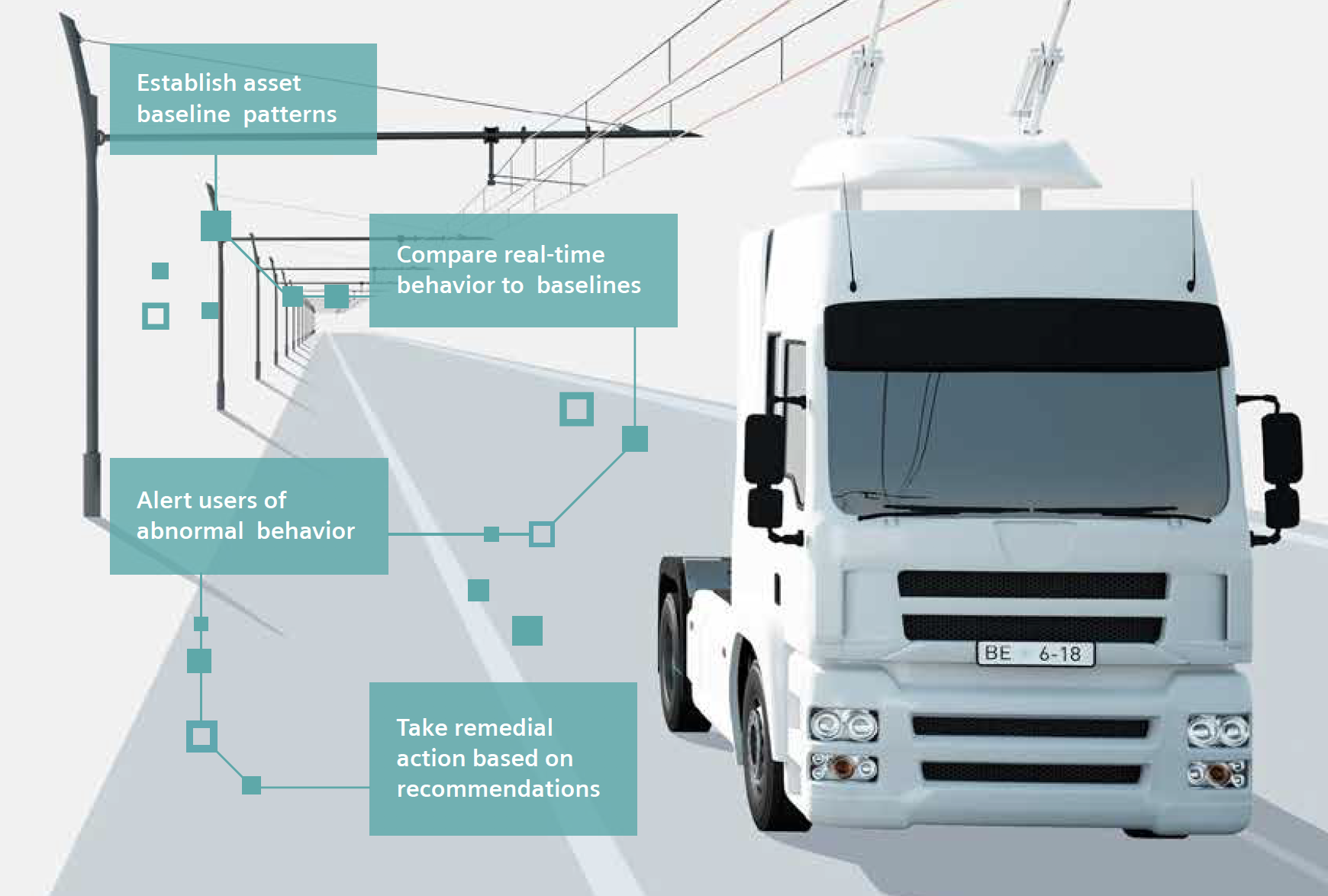

Find out in this infographic by Siemens how predictive maintenance can help.

Further reading: Unleash the Power of IoT-based Predictive Maintenance

Decreasing Industrial Inefficiencies through Asset Management and IoT