Rethinking MES Architecture for the Age of AI and Edge Computing

At the MES & Industry 4.0 Summit in Porto, Adélio Fernandes, VP of Engineering and Co-founder of Critical Manufacturing, shared forward-looking insights on how MES (Manufacturing Execution Systems) must evolve to meet the needs of today’s data-intensive, AI-driven factories. His

Subscription MES: A New Path to Digital Transformation

What if deploying MES didn’t require a massive budget, a year-long integration plan, or buy-in from every corner of the enterprise? A growing number of manufacturers are shifting away from all-in-one MES rollouts and embracing a more agile approach—building their

Still Using Excel on the Shop Floor? Why That’s Costing You More Than You Think

Despite years of digital transformation buzz, many manufacturers still rely on spreadsheets, paper-based records, and siloed systems to run critical operations. As Augusto Vilarinho, Head of Global Sales at Critical Manufacturing, bluntly put it during the recent MES & Industry

Why Edge-to-Cloud Data Symmetry Is the Foundation of Scalable Smart Manufacturing

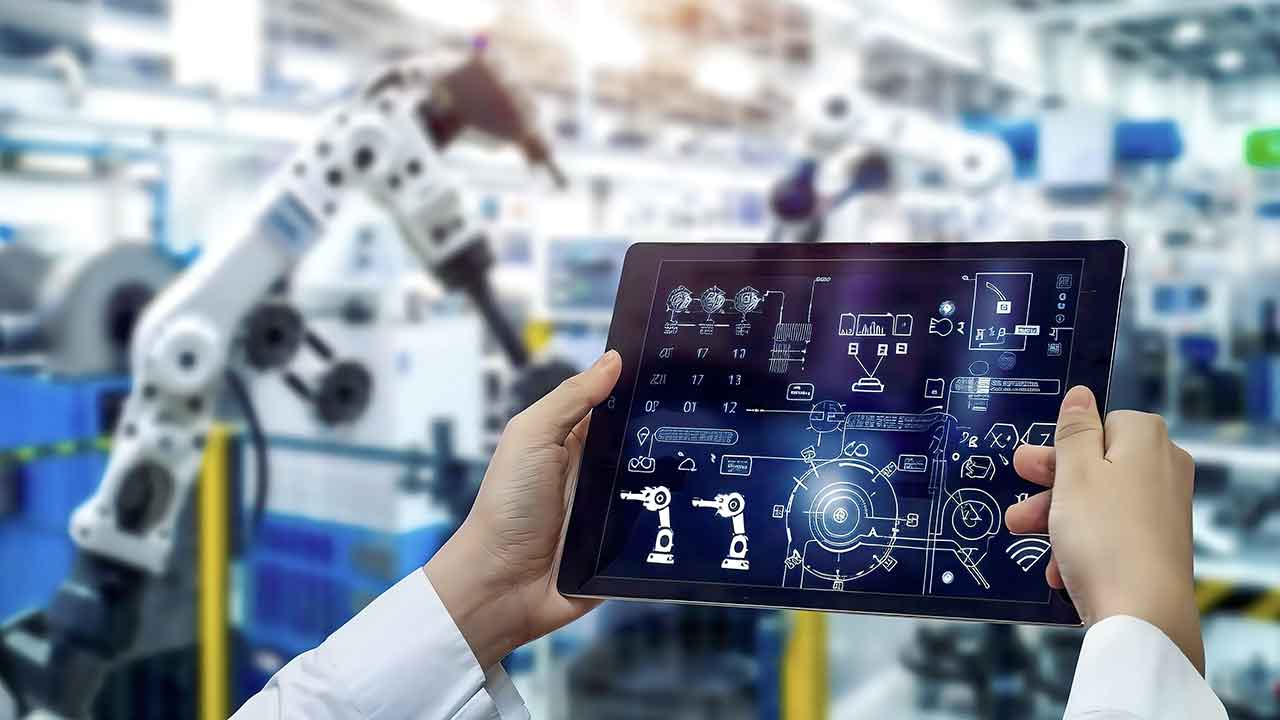

As manufacturers accelerate their digital transformation journeys, the limitations of fragmented data environments are becoming more visible—and more costly. The promise of smart manufacturing hinges on one capability: enabling data to move seamlessly from the factory floor to the cloud

What’s Next for MES? Find Out at MESI 4.0 Summit 2025 in Porto

As manufacturers continue to navigate evolving demands, supply chain complexity, and fast-paced technological change, the need for scalable, intelligent, and resilient systems is front and center. The MESI 4.0 Summit 2025, hosted by Critical Manufacturing, offers a platform for manufacturing and technology

The Digital Twin in Automotive: The Update

Digital twin technology, a virtual replica of physical products, processes, and environments, continues to evolve in the automotive OEM sector. It now spans the entire lifecycle of a vehicle, from research and development, engineering, and manufacturing to logistics, sales, aftersales,

[Booklet] Manufacturing at the Crossroads 2025: Real-World Lessons from Industrial Leaders

What does it take to make digital transformation stick—beyond pilots, platforms, and buzzwords? At Hannover Messe 2025, the conversation around industrial transformation reached a new level of clarity—and urgency. From AI and agentic automation to modular MES platforms and resilient supply

HighByte Adds Amazon S3 Tables for Smarter Industrial Data

In the ongoing effort to bridge the gap between operational technology (OT) and IT, HighByte’s latest announcement marks a significant milestone for manufacturers on their digital transformation journey. Today, March 31, 2025, HighByte announced native support for Amazon S3 Tables through the HighByte Intelligence

Critical Manufacturing to Showcase the Future of MES at Hannover Messe 2025

At Hannover Messe 2025, Critical Manufacturing will spotlight how next-generation Manufacturing Execution Systems (MES) can move manufacturers beyond incremental gains—toward measurable, transformative outcomes. As a recognized leader in MES by IDC MarketScape and a subsidiary of ASMPT, the company will