Digital Transformation Case Studies | SPONSORED

The manufacturing industry has been adopting next-gen technologies such as AI (artificial intelligence), advanced data analytics, predictive maintenance, automation, robotics, and more for improved productivity and enhanced safety on factory floors. Cutting-edge technologies can hold the key to optimizing uptime and productivity. Below are two digital transgormation case studies on manufacturers who implemented transformative technologies.

Case Study #1: Ansaldo Energia, digitizes two of its production sites in the Lighthouse Plant project

Ansaldo Energia, a leader in the energy sector with an innovative cutting-edge project called the Lighthouse Plant, digitized the entire manufacturing process of two production sites in Genoa, Italy, optimizing predictive production and maintenance processes.

The Challenge:

The digital transformation of Ansaldo Energia began years ago and covers all key process in the value chain, from marketing and sales through to product development that is increasingly integrated at a digital level with service activities, as well as embracing production, supply chain management, and the erection and startup of machines and plants. Ansaldo Energia will invest 14 million euros in a three-year industrial research and development plan based on the main digital technologies of the Industry 4.0 Plan. This project will affect the entire manufacturing process of two production sites to interconnect their machines. The collection of machine data, together with the extreme ease of management of the data, has made the process of digitizing the sites successful.

Case Study #2: A Multinational Group Faces a Complex Digital Transformation

Active on an international level with 15 plants in 7 countries and a turnover of 185 million euros, the Cornaglia Group confirms with its experience that research and analysis of the “data” are now strategic resources which help achieve competitiveness, cost control, savings and optimization of production processes.

The Challenge:

The practical objective was to have more careful control of production efficiency. It is necessary to know in real-time if certain production lines are working under target to understand what causes slowdowns and/or stops, and try to solve them in the shortest possible timeframe.

The path of Industry 4.0 was the only feasible way to be able to achieve the objectives, collect data directly from the field and the machines, and transfer it in a complete and orderly manner, in a way that provides insights and strategic information in terms of production, processing times, quality, etc.

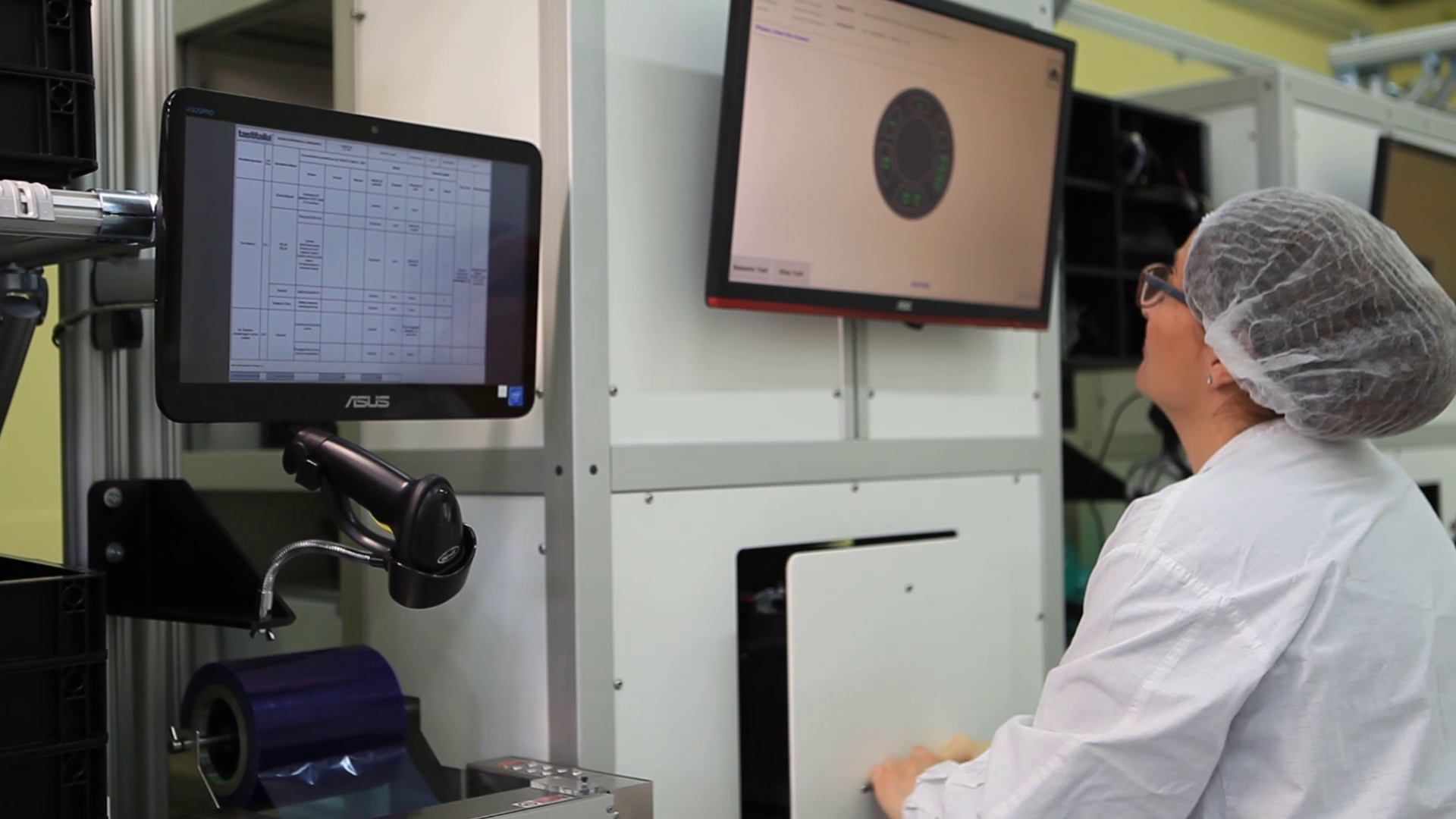

Case Study #3: Tastitalia connects a different kind of industrial machine to the Internet of Things

Tastitalia, an Italian company that creates customized solutions for human-machine interfaces, managed to control production costs and quality levels of their processes in an extremely precise and continuous way by interconnecting innovative machines to non-digital native machines.

The Challenge

There was an urgency to detect data from production processes in a punctual way, to implement an efficient production control in the company and to evolve the production system, from an Industry 4.0 perspective, into a market with very special machines. Tastitalia, with the help of tech partners including Alleantia, was able to automate the acquisition of a lot of information, improving data acquisition and analysis times and avoid all gaps and inaccuracies of manual entry, allowing them to obtain objective data.

Case Study #4: A historical Italian company, Paglieri, upgrades its production lines to Industry 4.0

The Paglieri success story is the perfect example of what it means to use the power of IIoT to rethink in a modern key the creation of an historical product. Discover how digitization enabled Paglieri to reach the highest levels of quality and transition to predictive maintenance.

The Challenge

For Paglieri, the evolution of manufacturing processes was born from the strategic choice to rethink their historic ‘Felce Azzurra’ product and to internalize the production of home care items for two factories, thus avoiding moving 40 million liters of product that were previously made by third parties. They chose to adopt an Industry 4.0 solution, supported by the use of Industrial IoT technology. The Paglieri investments included:

- The packing line of Felce Azzurra shower gel, in a re-vamping process.

- The installation of a chemical plant and a packing line which was completely new for the production of fabric softener, in order to take back production wholly inside the company.

About Alleantia

Alleantia is an Italy-based high-tech company committed to providing the most powerful and easy to use Industrial IoTedge solution, that enables lndustry, Owners and Machine Builders transforming industrial business through fast and cost-effective digitalization of industrial assets and products. lndependent Software Vendors, System lntegrators and OEMs, partnering with Alleantia, enrich and complete their offers to effectively address challenging Digital Transformations in manufacturing and Industry 4.0 projects.

Today, Alleantia is internationally known for its innovative software solutions applied to the “Industrial Internet of Things”. Alleantia’s solution can now be integrated into manufacturing plants, renewable energy plants, process and transport industries to guarantee every type of customer can reach the highest levels of productivity and plant maintenance.