What Does it Mean to Digitally Transform Manufacturing?

It is probably (hopefully) very clear to most manufacturers by now that not implementing some type of IoT or cloud strategy is really not an option in todays world. Not having a cloud strategy is not a strategy for manufacturers if you want to survive in this ever-changing, fast paced economy. Companies are experiencing a much higher velocity of business and technology change than ever before. The opportunities they see appear and/or dissolve in months and even weeks instead of years. There is a continuous stream of new services and startups that continue to disrupt in every industry. Companies have to be prepared to take advantage of those changes and disruptions to the market.

There are startups out there today that will and are changing how business is done. Some may not be known or show up in the news yet, but they will when that new way of doing business or that new way of manufacturing starts to grow. Who would have thought that Uber, Airbnb, Netflix, Spotify, and other new ideas would have taken off like they have.

Companies that aren’t transforming will be overtaken by these new businesses and new services that can enable their customers. Take for instance a traditional manufacturer that stamps out parts for machines or cars and ships these parts globally. There are 3D printing companies that are enabling 3D printing of parts from different raw materials…it isn’t just plastic anymore. 3D printing will enable new services that can quickly create new parts made from a number of materials on demand and will revolutionize global supply chains in manufacturing and other industries.

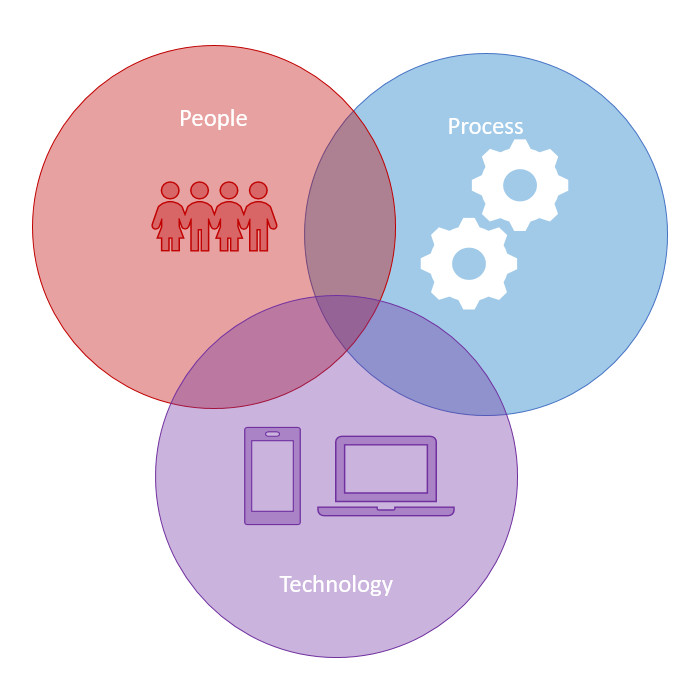

It Isn’t Just the Technology that Enables Transformation

Digital Transformation isn’t just about implementing technology. In manufacturing we talk about Azure IoT, connecting devices, and gaining insights on data to enable intelligent actions and we are now talking about the next step which is to use deep learning to actually have machines make the decisions that will shut off a process if a safety event occurs while a machine is running or send a command to a farm implement to tell it when and where to fertilize a field. While all that is part of the journey, it is the outcome of the journey. Lets face it, manufacturers have been doing IoT for 40+ years and they have tons of equipment in their facilities and data in their MES, Scadas, excel spreadsheets, ERP systems, and other data stores. Getting that data to the cloud and developing some analytics reports using PowerBI or other analytics tools that show missing inventory or lower OEE or improvements in efficiencies in processes and facilities can be done pretty quickly. But before you get there, you have to the right data fed from the right processes plus employees implementing and managing these processes.

If you only look at technology to transform your business, then you risk the consequences of not truly transforming and applying technology on top of inefficient processes. I talk to a lot of manufacturers who look at Azure IoT, OPC-UA, microservices, IoT Edge and other services as technologies that will enable them to move into the Industrie 4.0 revolution. Yes, these technologies are great for helping manufacturers go from a reactive, excel spreadsheet based manufacturer to enabling intelligent actions that enable new services and solutions for your customers but if implemented alone risk only providing lots of data into inefficient processes. Take for example a manufacturer who has a very large legacy MES application that has been built up over several years. The application and accompanying database have grown up together over time with updates and new data feeds added over the years. No one really knows all the feeds or processes or data flowing in because of its size and how it has evolved. If a manufacturer were to take this legacy application and database and do nothing more than attempt to break it up into microservices or shove some legacy code into containers, there might be some benefit. But what about all those business and manufacturing processes and systems that have been feeding this MES? Has anyone really reviewed the data and what is being fed into this system and where is that data coming from? Is there duplicate data? Is the data in the right format? Does it have data that is no longer needed or used? Does the application have code that is no longer needed or used or should be rewritten? Are there processes or operations that are feeding it that need to be revised and can be streamlined to be more efficient? To do microservices or apply any technology correctly, you really need to take a step back and look at the processes feeding the data.

Read more about Achieving Cutting Edge Production – A Guide to Machine Learning In Manufacturing

Ingredients for Transformation: People, Process, and Technology.

Just to show you an example that shows how a company can transform. It wasn’t that long ago that Microsoft shipped boxed products. We would ship Windows Server and other products on a two year cycle. If there were lots of requests from customers for some cool feature or there was other new technology we wanted to integrate with, it would basically be the next 2 year cycle before that update was put into the product. Microsoft had a pretty efficient well managed process back in the day. We have since moved to being able to ship new features in 3 week sprints and even faster in some cases. It didn’t happen overnight. It took changes to our processes of developing software, changes to how we organized our teams, applying new technologies like cloud infrastructure, new cloud services, adopting new ways to develop and build software, adopting open source, and many, many other changes across the company so that we could innovate quickly.

To innovate quickly, you need to enable people, your employees, and to innovate and adopt new processes and new ways of doing things. Talk to your employees and take a look at how to help them evolve skills and improve the processes. What are their ideas? What do they want to do differently? “Cobots” or Robots that can work alongside employees are enabling safety as well as speed and precision on manufacturing lines. No longer does a single person do a task but instead they work along side a robot to enable more efficiencies. The people within your organization can help enable innovation and you can help employees by enabling them to help transform the processes within your manufacturing business. If your company is still having employees fill out spreadsheets on a regular basis to understand the production line and costs, then look at improvements to the process and applying new processes and technology to enable your employees to do more and spend less time filling out spreadsheets. Changing how they function, how the process flows, and the technology that they use will enable them and your business to become more agile.

Manufacturers should not just think about OPC-UA, IoT Edge, Azure IoT for connecting their facilities and machines, but for every innovation or new technology you want to undertake, look at the processes that have been implemented and what changes should or could take place to improve that process and its efficiency, data accuracy, availability, production quality, operational equipment effectiveness (OEE), and other key improvements and metrics. The key isn’t either about just connecting to get data to the cloud. It needs to be the right data. Applying machine learning to inaccurate data will give you inaccurate recommendations and insights. The data comes from the processes. That’s way looking at the process that creates the data is so important.

No company can make these changes overnight. It is a journey. It takes time and it can be painful at times to go through the changes necessary. Don’t try to tackle a large end to end IT solution for manufacturing all at once. Think and plan for the big picture of what your business wants to achieve and then break changes down into manageable pieces and start where your company can realize business value quickly.

This article was written by Dottie Shaw who has a passion for making technology work for our customers. Dottie helps customers design and build applications for the Cloud and Edge in manufacturing and early adoption programs at Microsoft. Working with customers enables our teams to gain insights from customers to help shape our products, technologies, and how we deliver solutions. Originally the article was published on LinkedIn.

This article was written by Dottie Shaw who has a passion for making technology work for our customers. Dottie helps customers design and build applications for the Cloud and Edge in manufacturing and early adoption programs at Microsoft. Working with customers enables our teams to gain insights from customers to help shape our products, technologies, and how we deliver solutions. Originally the article was published on LinkedIn.