The Intelligent Manufacturing Journey: Accelerated by the New Normal | SPONSORED

It should come as no surprise to anyone that global manufacturing operations have been deeply impacted by the COVID-19 pandemic – with shocks to supply chains, pricing structures and growth strategies. What may be less obvious is how companies can intelligently use analytics to meet these challenges.

Sid Verma, general manager of the manufacturing practice at Hitachi Vantara, has a unique perspective on this. His company part of a more than 110-year industrial goliath that was one of the pioneers of electric motor production in Japan. The company not only has more than 60 years of experience in IT, but has also developed a framework for how to think about intelligent manufacturing.

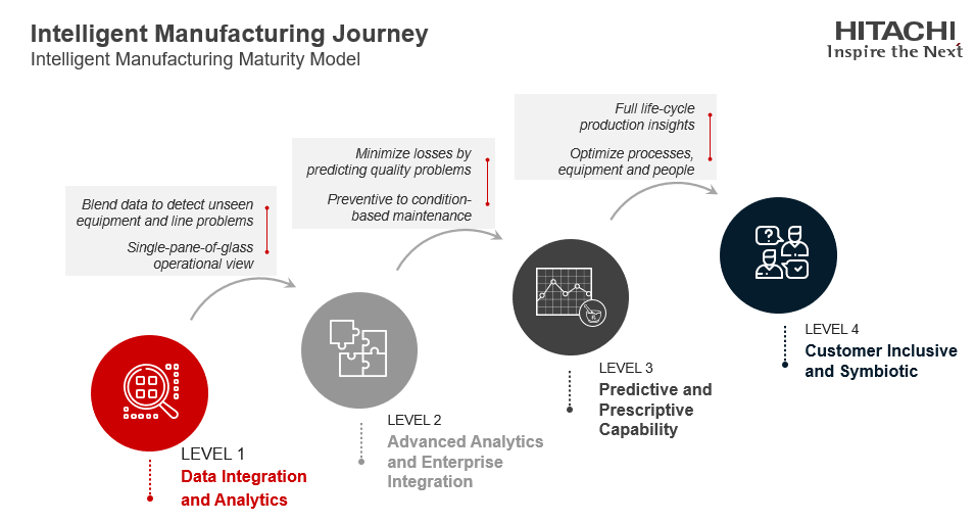

“We feel it is a continuous journey that Hitachi has followed and learned from. It’s something we are proud to share with our clients and our customers,” he explained in a recent presentation at IIoT World Days. “We call it the staircase to value for manufacturing maturity.”

According to Sid Verma, the journey starts with the assumption that not all customers start at the same level. He said that most manufacturers are at Level 1 or Level 2 – and that the big step change is from level 3 to level 4 with the realization that customer inclusion is central to Manufacturing 4.0

“The typical environment is heterogenous, islands-of-automation with several monolithic manufacturing systems and apps,” he added. “The challenge is to get insights that matter and gain control over key pain points. Our focus is to tackle issues that can drive business outcomes and provide you a pathway to progressively drive digital maturity.”

Verma also provided a dose of reality about the scale of the challenge for companies on this journey. He said that only a subset of industrial transformation projects – which he estimates as few as 11% – actually make it out of the pilot phase to a broader adoption and scale within the organization.

“Therefore, it’s important to look after some of the fundamentals of the process as you approach the initiative,” he advised. “You need to set clear goals and identify areas that need improvement. Then come up with smaller projects that provide a proof of value and are clearly supported by the leadership team and the organization. It is also important to focus on what really matters to get results and leverage outside experience as you undertake the journey.”

He further suggested that organizations should avoid a wholesale “rip and replace” strategy for their existing infrastructure as they approach this challenge – and instead prioritize and sequence investments and initiatives with business outcomes and value as the key driver of the work.

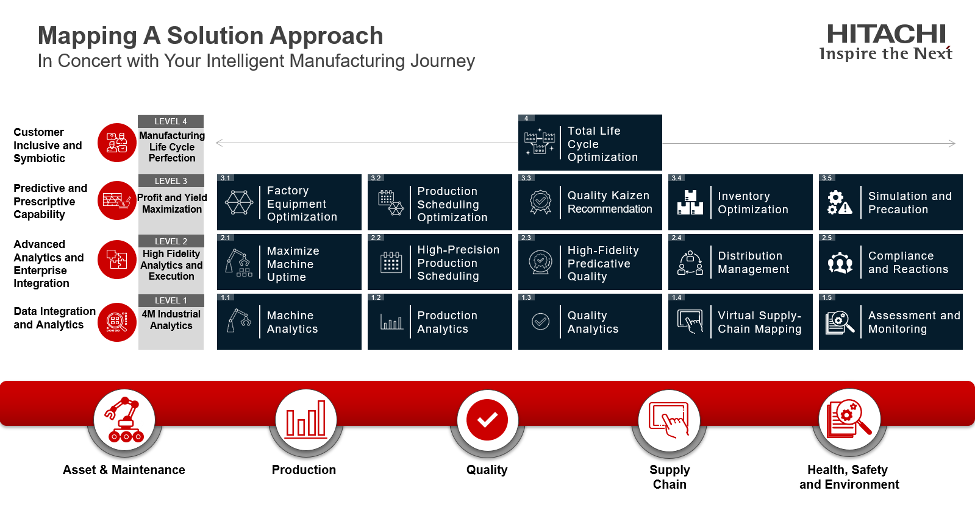

In terms of making it happen, Verma recommended a solution approach grounded in the work you know that the organization needs to tackle. “The central idea is to accelerate the descriptive, predictive, prescriptive and customer inclusive approach across each critical area of manufacturing operations – asset & maintenance, production, quality, supply-chain and health, safety & environment,” he said. “Organizations can have different levels of maturity across Level 1 to Level 4 for different areas of their manufacturing operations. The key is to focus on what is important for your operation and create a foundation for digital industrial transformation.”

Verma was also realistic about the key challenges that organizations face in implementing digital transformation – and offered some ideas on overcoming them. “There are several key challenges that come to mind. People can be barriers to adoption so having buy-in by organizations at every level is key”, he said. “Also, it’s necessary to have the right level of experience in implementing IoT solutions and this is where a partner can really help. You want somebody who has already gone about it and is willing to work closely with your organization to get results. This is a role that Hitachi often assumes when we help guide our customers through their digital transformation.”

Over and above the need to have the right partner, Verma said that while it is important to pick out specific pilot projects, organizations should not forget that the overall goal should be a digitalization strategy that supports the business with major outcomes identified and tracked.

“You also need to make sure you have adequate budget and executive level support for the projects that you undertake,” he concluded. “One good way to approach this is to make sure you have stages set up in a multiyear plan, a roadmap that will get you where you want to go rather than trying to spend all the money in one year and one budget cycle.”

More about The Roadmap To Digital Manufacturing Transformation

This article is sponsored by Hitachi Vantara

About the Author

This article was written by Geof Wheelwright, IIoT World Contributing Author, a technology journalist for more than 25 years (including work for The Times of London, the Financial Times, Newsweek, Time Magazine, The Guardian and trade publications such as Computerworld and Geekwire).

This article was written by Geof Wheelwright, IIoT World Contributing Author, a technology journalist for more than 25 years (including work for The Times of London, the Financial Times, Newsweek, Time Magazine, The Guardian and trade publications such as Computerworld and Geekwire).