Case study: How the world’s largest flooring manufacturer uses IIoT solutions to reduce costs

World’s largest flooring manufacturer improves operational visibility and reduces costs with Cisco solutions.

Taking Sustainability to the Factory Floor

For Mohawk Industries, sustainability isn’t just a marketing buzzword. It’s a value woven deep within everything the manufacturer produces. A world leader in residential and commercial flooring, Mohawk operates hundreds of plants across the United States and globally. The company manufactures not only carpet, but many other flooring materials. And it does it responsibly and efficiently, as part of its Mohawk GreenWorks™ sustainability initiative.

For example, Mohawk operates the world’s largest integrated plastic bottle facility in Summerville, GA, using this innovative material as a basis for its EverStrand® brand of carpeting. The company recycles about 5.5 Billion plastic bottles per year. In fact, one out of every four bottles recycled in North America becomes part of an EverStrand carpet. Bottles from recycling plants are sorted, and ground up and cleaned. Then they are combined with resin to create polyester fibers that are spun into soft, durable carpet yarn.

“Turning recycled plastic into carpets is our way of sustaining the planet for our children and grandchildren, eliminating waste and leaving things better than we found them,” says Jana Kanyadan, Senior Vice President and CIO at Mohawk.

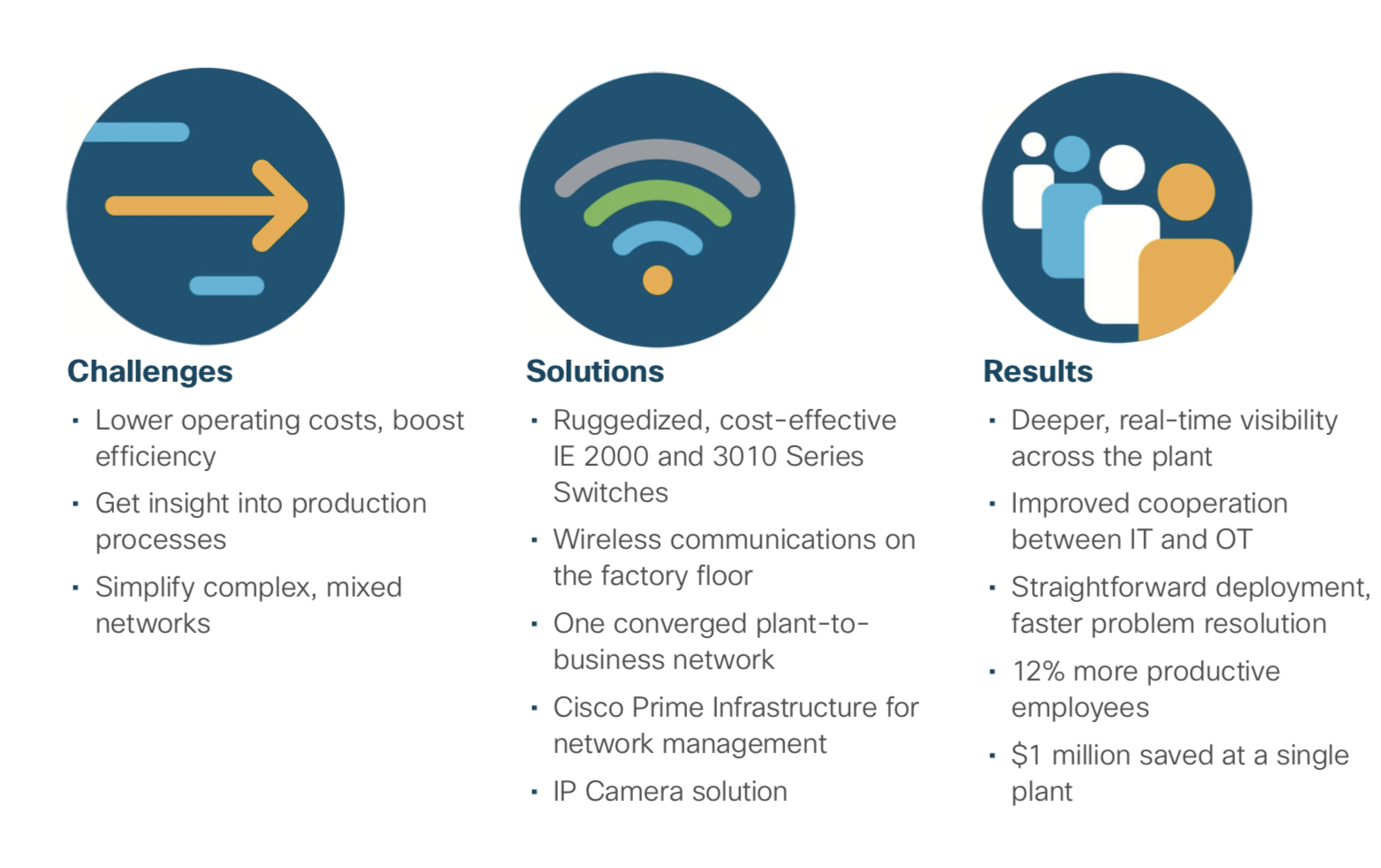

When it was time to expand the Summerville plant, Mohawk wanted to make its operations even more streamlined and efficient. But its factory environment was a complex mix of network and production equipment. Getting better insight into all the data that these devices produced was key to building a greener factory. To achieve it, the company turned to Cisco.

“We rely on data to give us insight into the entire production line, so we can make realtime decisions based on real-time activities,” says Jevin Jensen, Vice President of Global Infrastructure at Mohawk. “If each of our machine lines are on different networks, we couldn’t see the big picture.”

Understanding the Big Picture

To see what was really happening in its factory, Mohawk retrofitted its Summerville production line with sensors and devices, all connected through the Cisco Industrial Ethernet (IE) 2000 Series Switch. Built for harsh, dusty plant environments, the IE 2000 lets Mohawk bring together its industrial and enterprise networks, gathering detailed real-time production data.

Mohawk brings information from these switches to more than a dozen Cisco IE 3010 Series Switches connected by fiber and copper wire. These secure, ruggedized rack-mount switches support leading Industrial Ethernet protocols for manufacturing and automation.

How does Mohawk keep its factory and enterprise networks separate and secure? Using a Cisco Validated Design, the company set up a secure, firewalled “demilitarized zone” (DMZ). Automation engineers can access the network via 24 virtual local area networks (VLANs), which are segmented for even more data security. The Cisco Prime network management solution provides control and visibility into all these networks, technologies, and services.

By moving from a proprietary approach to an open Internet of Everything infrastructure, Mohawk has set the stage for better visibility, efficiency and productivity.

“Before, we would have a lot of proprietary control system protocols: ControlNet, DeviceNet, Data Highway Plus, Modbus, PROFIBUS, and so on,” says Jensen. “To take that information from the plant floor and make it usable for analysis was a nightmare. Ethernet/IP combines all these different protocols onto one common standard to help us make real-time decisions based on realtime activities.”

As a bonus, the solution’s wireless capability, based on the Cisco 2600 access point—at first considered an extra—has turned out to be a game changer.

“It makes our lives easier. The whole engineering team is now able to monitor and assess metrics right at the site of the sensor or device,” says Jensen.

Less Downtime Means Lower Costs

Putting all this production data in reach has made life easier for Summerville plant managers. They’re especially pleased with more automated, proactive monitoring and troubleshooting on the production line. Previously, multiple engineers had to be on duty 24 hours a day to physically man and monitor the equipment. Now, they can simply be on call. If the automated system alerts them about a problem, they can simply log into the network and check it out. A single engineer can monitor the entire network through one centralized control room.

The new solution also helps Mohawk save money, and build a safer, more productive workplace. Employees are now 12 percent more productive, and a single plant has saved one million dollars in just one year, after deploying the Cisco solution.

“With Cisco, the common wireless standard not only lets us track every roll of carpet but it has allowed us to deploy new technologies like automated driverless forklifts, giving us better productivity and employee safety,” says Kanyadan.

And by deploying a unified Cisco solution in the plant and corporate offices, Mohawk only has to train its employees once. IT and engineering personnel (together with Cisco) were up to speed in just hours. “The IT/engineering cultural divide can be a huge barrier,” says Jensen. “After one session, some of the control engineers said, ‘I learned more in that one meeting with Cisco than we learned over the past three years with all the other vendors we’ve dealt with.’”

When employees need support assistance, they can get the answers they need from Cisco’s Total Access Care (TAC) support system. Most issues can be resolved within hours, instead of a week or more under the previous system.

Towards a Greener Future

As it expands, Mohawk is also making its processes more efficient, producing more carpet fiber to meet consumer demand. The proven Summerville installation is now being used as a template for similar converged solutions at all the company’s plants. The plan is to expand into at least five or six plants per year, with complete deployment expected in three years or less. Mohawk also plans build on its new Cisco foundation by adding physical security and surveillance, as well as a new regional control operations center.

“We never expected installing our new industrial networks to be this easy,” Kanyadan concludes. “We have been able to deploy, debug, and resolve issues in a remarkably short period of time. The key result, at the end of the day, is that it works.”

With its successful Cisco solution in place, Mohawk is looking forward to rolling out more sustainable manufacturing one plant at a time.

To learn more about the Cisco solutions featured in this case study, go to cisco.com/go/manufacturing. To download this case study, click here.