Smarter Factories, Safer Workers: AI-Driven Innovations in Industrial Monitoring

At this year's Hannover Messe, Stephane Daeuble, Head of Enterprise Campus Edge Solution proposition & Market Development at Nokia, shared his insights on the evolving landscape of industrial IoT. The conversation highlights Nokia's strategic initiatives in enhancing digital transformation across

Smart Factory initiatives – main driver of manufacturing competitiveness

Smart Factory initiatives – main driver of manufacturing competitiveness Smart Factory is a concept until recently considered futuristic, but now translated into reality by the existing technologies on the market. Relying on cybernetic systems that communicate with each other, Smart Factory is based

Making the transition to the smart factory: Areas for consideration

IIoT technologies are driving the manufacturing industry to modernize its software infrastructure to create smart factories. A key motivation in this push to modernize is that real-time data and dynamic decision-making yield meaningful performance improvements for businesses. Current manufacturing infrastructure is

Virtualization in the Factory

Virtualization, which in recent years has taken increasingly important steps, has become the model of integration and management of systems with the most promising evolution. Virtualization also means rationalizing the use of a network, of a data storage resource, of

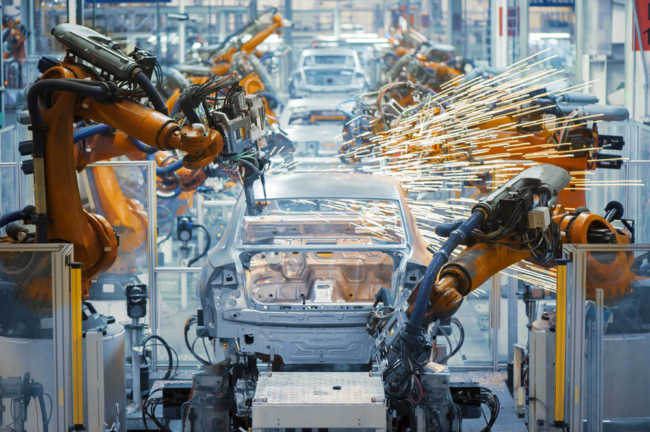

How to transition to a Smart Factory with Siemens and AWS

Making a factory smart means taking advantage of the Industrial Internet of Things (IIoT) – technologies that collect and centralize mass amounts of machine data gathered from industrial environments and create value from that data. Solutions built on IIoT platforms collect, aggregate, analyze, and

Smart Factory Case Studies

This summary contains three Smart Factory success stories in IoT manufacturing, from the Semiconductor, Manufacturing and Electrical Engineering industries. They describe how Trend Micro expertise and solutions addressed a variety of business challenges, including security solutions for cloud infrastructures, connected

Real Threats Logs From a Smart Factory Honeypot

Trend Micro just published the results of a six-month honeypot imitating an industrial factory. The highly sophisticated Operational Technology (OT) honeypot attracted fraud and financially motivated exploits. The six-month investigation revealed that unsecured industrial environments are primarily victims of common threats.

How to Make Sense of Machine Data in Smart Factory 101

“Digital transformation” and “smart factory” are the terms that have been around for a while, but only advanced manufacturers apply them to practice. The idea of machine to machine communication has raised the initial excitement and high hopes but now

[New ebook] Improving Operational Efficiency with Industrial IoT

A study by the American Association for Quality found that businesses shifting to digital processes and Industrial IoT have seen as high as 82% increase in efficiency accompanied with 49% less defects! Production on the shop floor is the most obvious place to start when looking