Using Augmented Field Procedures to Improve Worker Safety and Efficiency in the Energy Sector

Irrespective of industry or activity, when a human is performing a task, there is a possibility for error. There are numerous studies showing the impact of inadequate procedures towards human error, which led to severe incidents, significant downtime and overall operational losses. As companies begin to embrace digitalization via IIoT, a key challenge still remains: ‘How do we significantly minimize human error in heavily paper-based operating and maintenance procedures?’

Put the Power of Industry 4.0 in the Hands of Field Workers

Making a step change in minimizing human error while increasing workflow efficiency will enable a safer working environment and drive improved profit potential. ABB has developed an innovative technology, ABB Ability™ Augmented Field Procedures, aimed at digitalizing the field operator experience and improving interaction between field and control room operations.

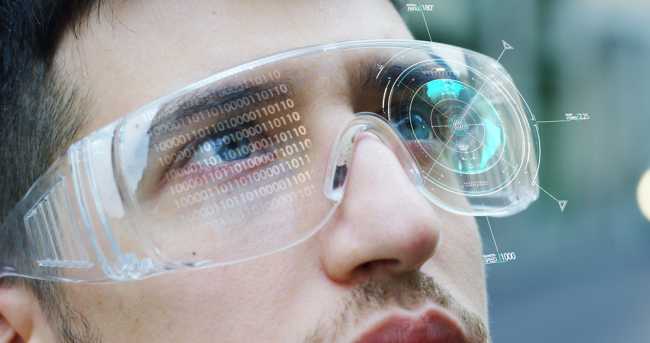

Developed specifically to meet the needs of field operators, this technology will empower seamless integration between the field and the plant distributed control system offering improved safety, reducing the risk for human error and making field operations more efficient. The additional application using augmented reality can be used for training purposes when hands free operation is key.

With more than 20% of industrial downtime reportedly due to human error, ABB Ability™ Augmented Field Procedures will enable consistency when executing manual procedures, standardizing operating procedures and maintenance or repair techniques in the field, tightening field to control room integration and digitally recording notes to ensure operational knowledge is captured and utilized. Unlike traditional paper-based checklists, manual rounds and standard operating procedures (SOPs), the technology enables interactive execution of procedures using a mobile device to guide operators through each step in a consistent, effective and safe way.

Leverage IIoT Technology for the Connected Operator

Operators will be able to access hands-free, real-time data related to plant assets, processes or procedures using industrial tablets, smart phones and Microsoft HoloLens glasses, increasing real-time collaboration and enabling immediate data entry from the user interface in the field. Created in collaboration with industry majors, the system can be used in any industrial environment, in greenfield and brownfield sites, for start-up, routine maintenance, and shutdown activities.

Supporting operators across oil, gas, chemical, process, power and water sectors, it will help transform plant operational procedures, putting the power of IIoT, digitalization, mobility, and connectivity into the hands of field workers. The solution is an example of ABB’s support of workforce management enterprise applications designed to allow workers to work anywhere and manage the system on their own.

Visit the website for more information on ABB Ability™ Augmented Field Procedures.

![]() This article was written by Chris Naunheimer, Digital Lead, Energy Industries at ABB. Chris has more than 20 years of experience at multi-national Fortune 500 industrial companies with leadership roles in engineering, R&D, strategic marketing, new product ventures, and user-centered design. Over his career, he became a named inventor on 25 granted US utility patents and brings this innovation and continuous improvement mindset to teaching. This mindset, coupled with his user experience design education and industry experience, brings a broad cross-functional skill set to his roles at Northwestern University.

This article was written by Chris Naunheimer, Digital Lead, Energy Industries at ABB. Chris has more than 20 years of experience at multi-national Fortune 500 industrial companies with leadership roles in engineering, R&D, strategic marketing, new product ventures, and user-centered design. Over his career, he became a named inventor on 25 granted US utility patents and brings this innovation and continuous improvement mindset to teaching. This mindset, coupled with his user experience design education and industry experience, brings a broad cross-functional skill set to his roles at Northwestern University.