How 3D Pallet Detection Systems Help Automated Forklifts Modernize Warehouse Operations | SPONSORED

The right 3D sensing system can help automated forklift trucks (AFT) achieve better than 98.5% pick accuracy and reduce mission time while simplifying even the toughest high-rack operations.

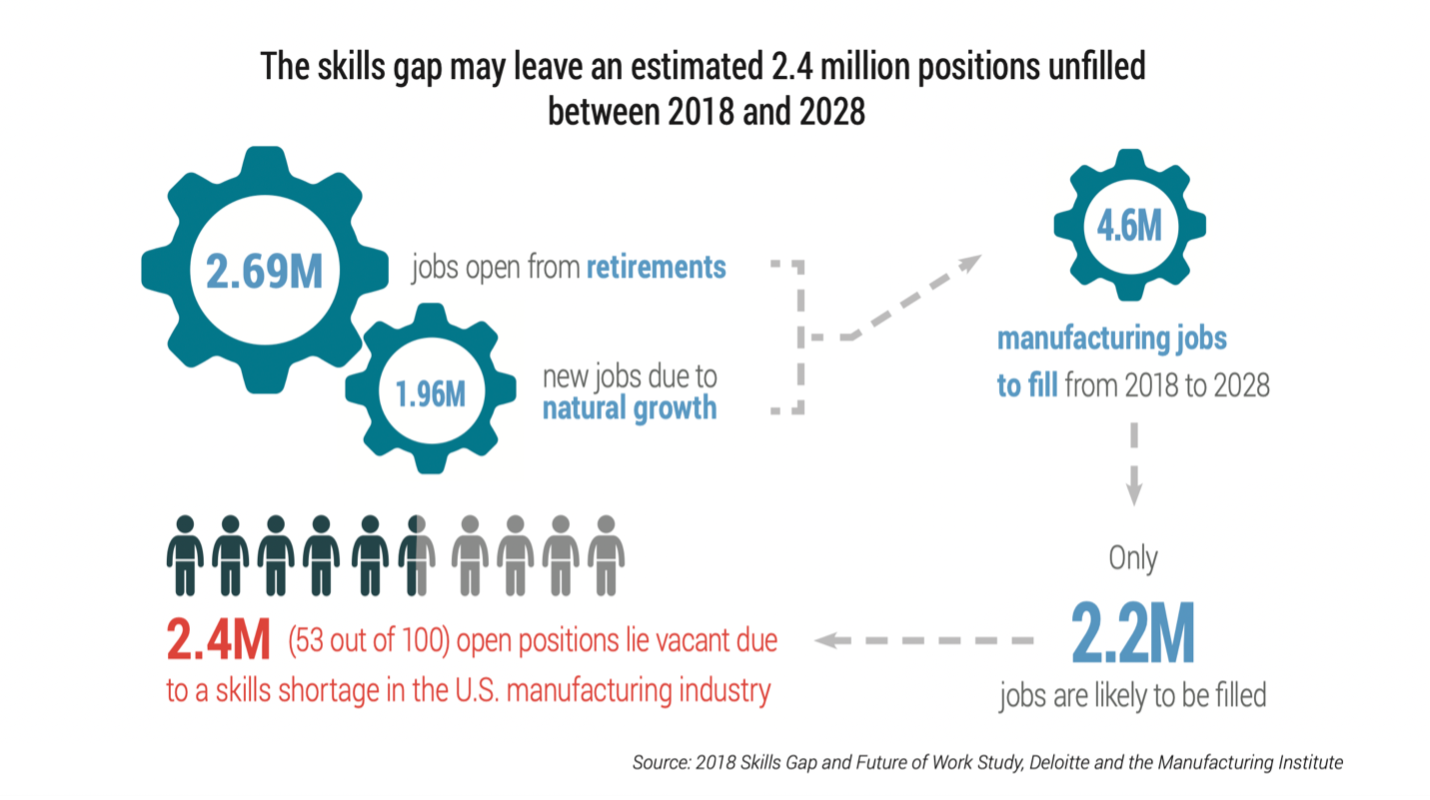

In the spring of 2018, for the first time ever, the U.S. Bureau of Labor Statistics (BLS) reported that there were more job openings than job seekers.

While U.S. manufacturing is the poster child for the labor gap — the National Association of Manufacturers (NAM) predicts that more than half of the 4.6 million manufacturing jobs created during the next decade will go unfilled — logistics, warehousing, and distribution are feeling the pinch too, victims of their own success and escalating e-commerce business trends. The pressure on warehouse operators isn’t likely to go away anytime soon. One way companies will fill the labor gap, the research company Technavio says, is through the adoption of technology, such as machine-readable bar codes and robots, to “increase speed and reduce errors in the order fulfillment process.” Automation offers a way forward for warehousing and logistics companies despite a lack of trained, certified workers, such as forklift operators.

Today, many logistics companies are leaving business on the table due to a lack of workers, but that isn’t the only financial pressure. In addition to lost potential revenue, warehouse operating margins are being squeezed by the need to pay overtime to keep operations going. In the past, only a few warehouse and manufacturing organizations had the financial wherewithal to automate forklift operations. Why the high capital costs? The technical challenges of fielding automated forklift trucks (AFTs) for the safe pick and rack of palletized goods are not trivial, and the infrastructure investment is sizable. Today, however, lost revenues and higher labor costs are changing the return-on-investment (ROI) calculation for the better, helping warehouse operators financially justify new ways of automating their operations. At the same time, new low-cost sensing systems, such as 3D machine vision, are helping reduce infrastructure requirements while improving the accuracy, speed, and safe operation of AFTs in messy real-world warehouse environments.

Find out how Pallet Detection Systems Can Help Automated Forklifts Modernize Warehouse Operations in this white paper sponsored by IFM.