[Use case] Improved machine performance using moneo Real-time Monitoring System | SPONSORED

A large manufacturer with assembly and sub-assemblies mass produces automotive parts and components. A plant of this magnitude requires equipment, such as motors, pumps, compressors, fans, vibratory feeders, and other machines.

- The manufacturer had incurred significant financial losses, experiencing bottlenecks that caused unplanned downtime and increased scrap rates.

- Predictive maintenance programs lacked process visibility and did not include intelligent warning and alarm systems.

- Different types of equipment had different parameters and there was no one system to collect the information.

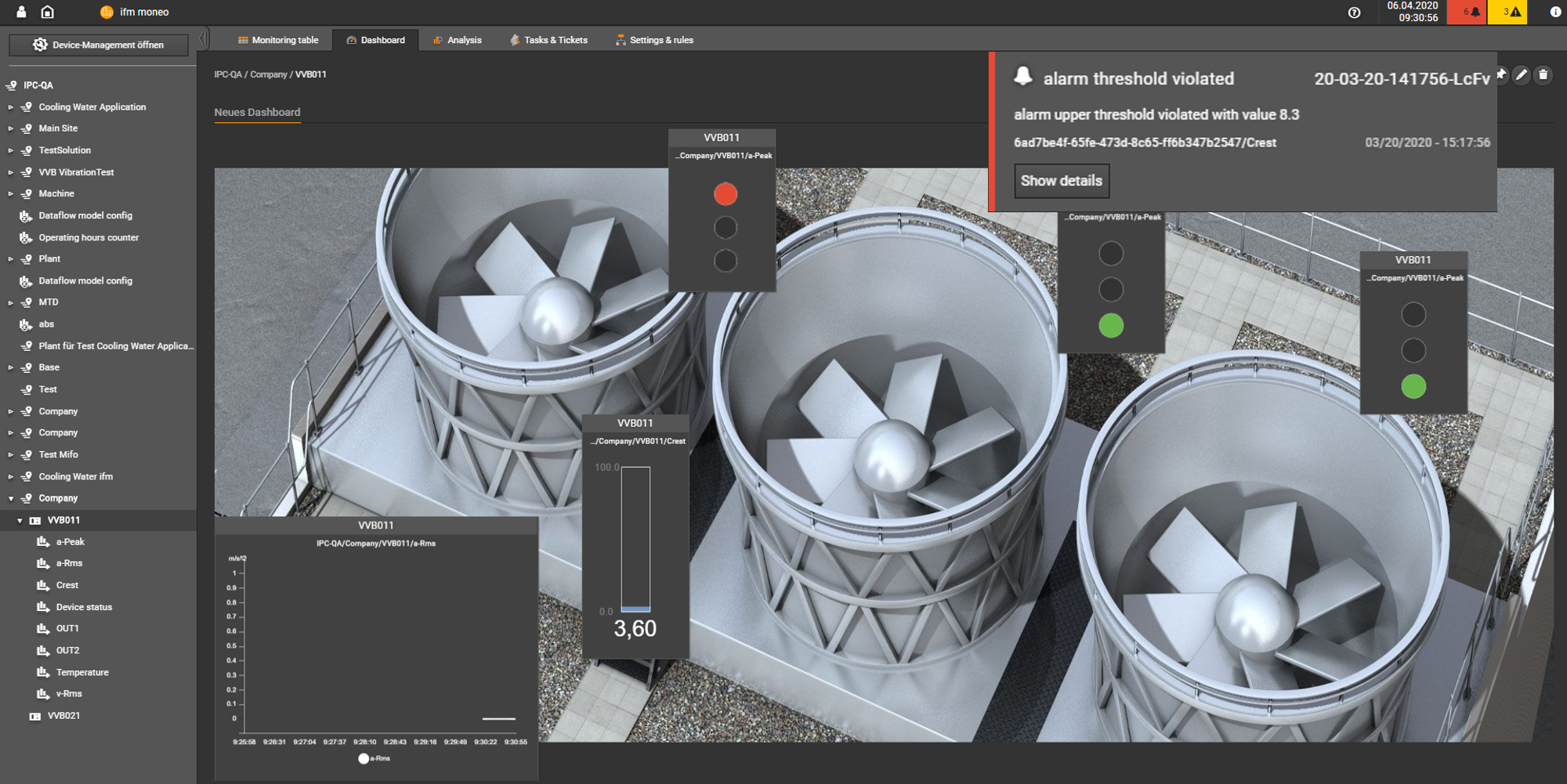

IFM’s moneo Real-Time Monitoring System maximizes machine performance by monitoring the vibration value of each piece of equipment in the plant.

The system detects changing conditions, displays the results, and sends a warning before damage occurs. moneo is easy to program and is user-friendly, which frees up the maintenance team to do value-added work versus time-based maintenance checks. moneo platform aligns corporate goals with Industry 4.0 initiatives.

Read more how moneo platform detects changing machinery conditions and improves performance in this case study by IFM.

Sponsored by IFM