The Advantages of Micro Data Centers in Industrial Edge Computing

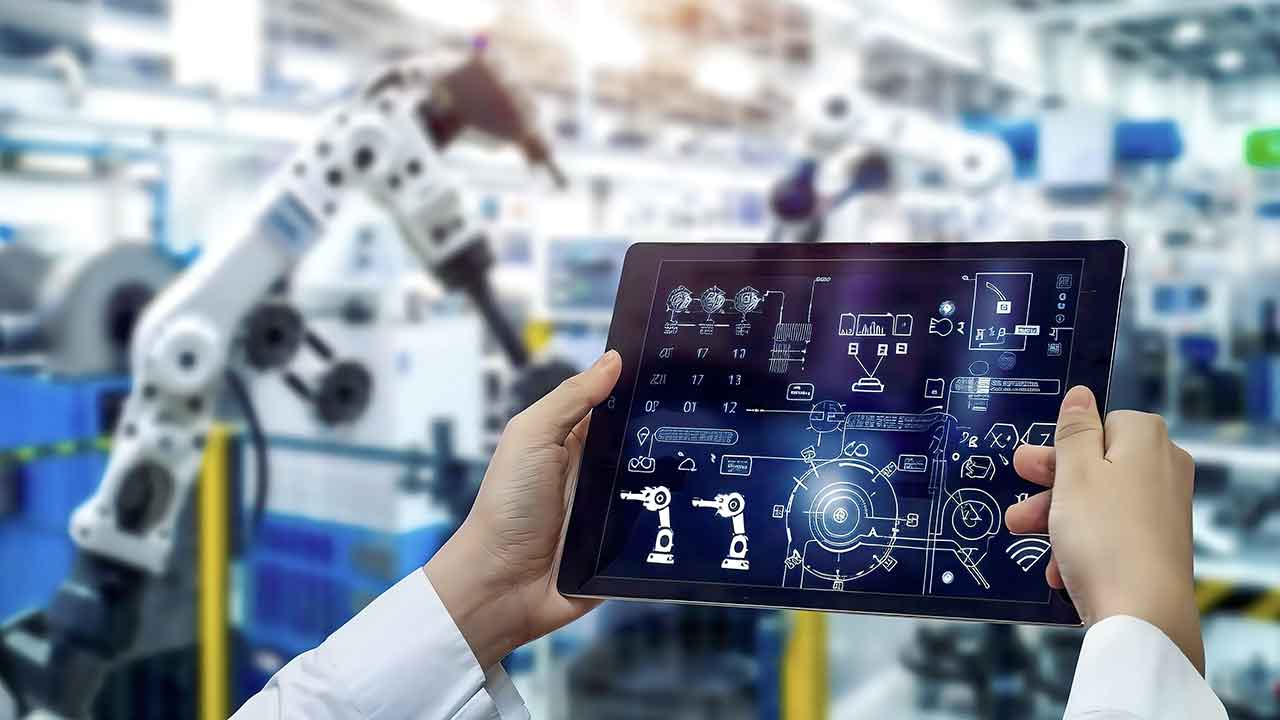

The benefits of industrial edge computing are becoming more apparent across a variety of industries. It brings low-latency compute capacity closer to applications and in the process, makes real-time data processing faster. Yet, building an edge computing solution can take a lot of work.

If you’re manufacturing goods in a factory or producing safe water or clean power in a facility, you would start by designing an architecture that uses edge computing platforms loaded with the best software you can find for monitoring and control. By installing data collection on-premise at the edge, you also eliminate bandwidth and latency issues as information is transmitted to the enterprise and cloud.

The whole process is long and involved, requiring a fair amount of research and consultation to ensure the best possible combination of IT and OT components. In addition, you are likely to communicate with multiple technology providers and distributors just to put a plan together.

There is a better way. It involves deploying a pre-configured, pre-validated hyperconverged infrastructure micro data center (MDC) that combines all the necessary components. This approach includes software pre-installed in a redundant and cybersecure edge computing platform, networking hardware, and power management via a Smart-UPSTM. This solution can accelerate industrial edge computing deployments by reducing field engineering time by 40%, with 20% faster time to market and 7% lower maintenance costs.

But who puts it all together?

The power of partnership for industrial edge computing

We have a partnership with Stratus Technologies to deliver end-to-end edge computing solutions. Stratus is all about downtime prevention and workload consolidation. It does this by delivering scalable, flexible, and operationally resilient systems with built-in redundancy and virtualization that comes in a single, integrated, edge computing platform.

A third partner, AVEVA, provides the industrial operations software, leveraging reference designs that specify the components and configuration needed for quick deployment at the edge. Reference designs map out the needs of industrial edge installations, so you don’t have to be an IT expert.

Avnet, a global distributor and solutions provider, brings all the components together. Avnet provides a one-stop shop for end customers, integrators, and OT distributors to order a complete, integrated turnkey solution. Each solution starts with a standardized offering approved and validated by the manufacturing partners. As Avnet builds the MDC, an integration partner works on customizing the virtual machines (VM) that are later integrated into the overall solution.

Bringing decades of experience in the IT and OT markets to each project, Avnet takes the complicated work of doing the build-out off the customer’s internal engineering teams, enabling them to focus on their key competencies.

Avnet also is able to provide a project estimate much earlier in the process than if you were putting together the solution on your own. Estimates usually fall within plus or minus 10% of the final cost. Getting the estimate early helps move along the project.

A simplified and faster digitalization journey

Leveraging the Schneider partnership with Stratus, AVEVA and Avnet makes for a much more streamlined and simplified journey, whether you’re an end user or system integrator. If you’re the end customer, you need only deal with one company, as opposed to four or five.

The original version of this article can be accessed here.

About the author

This article was written by Paolo Colombo, the Go To Market Director for Machine Builder and System Integrators at Schneider Electric.