Enhancing Operational Efficiency Through Data-Driven Insights in Manufacturing | SPONSORED

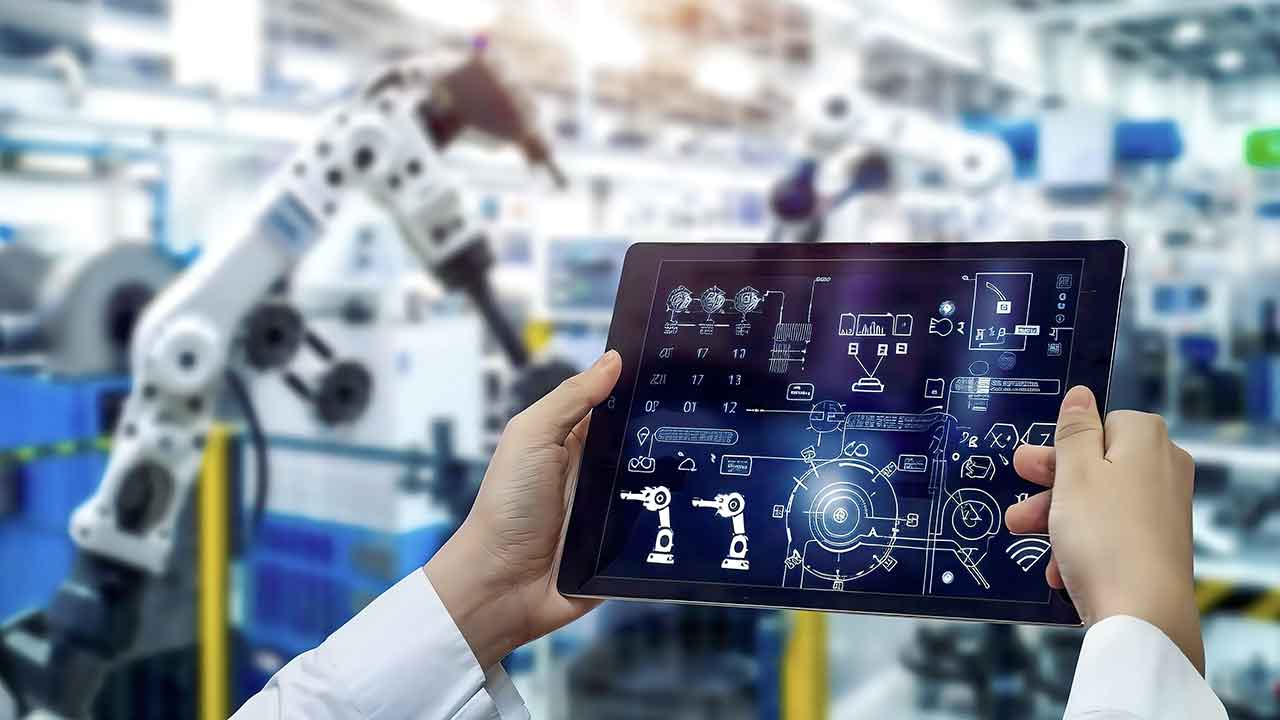

In the realm of industrial manufacturing, the digital era has ushered in unprecedented opportunities for efficiency and productivity. However, the journey towards digital transformation is fraught with challenges, not least of which is the underutilization of the vast amounts of data generated by industrial operations. A recent study by AWS and Frost & Sullivan study revealed a striking insight: less than 5% of plant data is currently being converted into actionable insights. This gap between data collection and data utilization underscores a critical need within the industry: the need for solutions that not only gather and aggregate data but also transform this data into meaningful, actionable intelligence that can drive operational improvements across multiple sites.

Schneider Electric announced recently the EcoStruxure Plant Lean Management, a software platform that doesn’t play favorites with hardware and marks a big leap forward in making factories more digital. It comes packed with tools that give the people working on the shop floor the power of real-time data they can actually use. At its heart, it’s all about setting up key performance indicators (KPIs) for those quick catch-up meetings, helping teams go through their production processes, spot where things are slowing down, and make the right moves to fix problems fast and efficiently.

The software’s user-friendly collaborative interface digitizes and optimizes SIM meeting cycles, facilitating a seamless flow of information across one or multiple sites. By automatically collecting relevant Information Technology and Operational Technology data for KPIs on productivity, service levels, quality, safety, and sustainability, the platform ensures real-time access to crucial data, thereby enabling users to visualize issues as they arise and track preventative and corrective actions until resolution.

Moreover, the integration of EcoStruxure Plant Lean Management with AVEVA Data Hub amplifies its potential by aggregating and storing vast quantities of real-time data generated by Industrial Internet of Things (IIoT) devices. This integration not only accelerates digital transformation efforts by eliminating the need for proof of concepts but also enhances manufacturing performance through faster issue escalation, decision-making, and problem-solving.

The value of EcoStruxure Plant Lean Management is not merely theoretical but has been proven in practice, with more than 70,000 operators leveraging the technology in Schneider Electric’s smart factories. The results speak for themselves: operational efficiency improvements of up to 5%, a 33% reduction in shift handover activities, three times faster issue resolution, and an acceleration of digital transformation efforts on an open, scalable, and cyber-secure IIoT platform.

For industries looking to navigate the complexities of digital transformation, the key lies in empowering their workforce with the right tools and data to make informed decisions.

Related resources: