Paul Viorel

What Makes the Difference Between an IIoT Pilot That Stalls and One That Scales?

Across the industrial sector, many companies launch promising IIoT pilots. Yet only a fraction of them manage to expand those proof-of-concepts into enterprise-wide deployments. The difference isn’t usually about ambition—it’s about execution. At AI Frontiers 2025, our speakers explored this very challenge, outlining what separates pilots that fizzle from those that successfully scale.Data Foundations FirstScalable […]

Read more →

Trust, Security, and Human Factors in Agentic AI

Autonomous AI on the factory floor is not just a technical challenge — it’s a human one. Operators want to know they can trust the system. Executives need accountability. Security teams demand resilience. At the “Agentic AI in Manufacturing: From Copilots to Autonomous Systems” session during AI Frontiers 2025, organized by IIoT World, audience questions cut straight […]

Read more →

Is a PoC the Right Path for Manufacturing AI?

PoCs get a bad rap in factories—they often feel like science projects that never leave the lab. They don’t have to. When a PoC is designed to prove scale, not just possibility, it becomes the fastest path to real plant results. This piece distills a candid question from AI Frontiers 2025 into a practical, no-fluff playbook drawn from […]

Read more →

AI in Energy: Why Progress Depends on People and Structure

When you talk with energy executives today, there’s no longer a debate about whether artificial intelligence belongs in operations. The question has shifted to how to make it work.Natalia Klafke, Executive Vice President of Energy & Sustainability at Radix, has spent over a decade helping energy companies modernize complex operations. At Impact 2025, she noted a clear […]

Read more →

Modernizing Without Disruption: A Practical Approach to Industrial Data Growth

Industrial operations depend on data historians to record what’s happening on the line or in the field. But as systems evolve toward Industry 4.0, many teams find that their historians weren’t built for what’s next — the volume, velocity, and variety of time series data now generated by sensors, PLCs, and edge devices.Replacing these systems […]

Read more →

The Most Effective Strategies for Integrating Agentic AI Into Legacy Manufacturing Environments Without a Full Overhaul

Answering the audience’s questionsManufacturing is not a greenfield playground for shiny new technology. It’s a world of legacy machines, siloed data, and decades-old dashboards that keep production running. Into this reality comes agentic AI—a powerful but new tool promising faster decisions, smarter insights, and measurable improvements.But for manufacturers, the big question isn’t what agentic AI can do in […]

Read more →

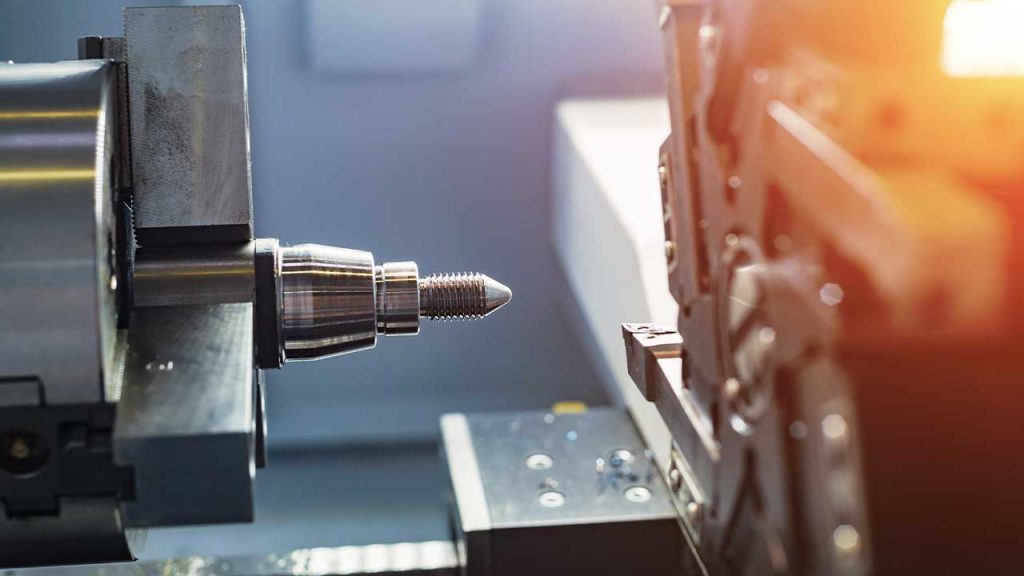

How AI and the Digital Thread Improve Machine Tool Systems

Artificial intelligence and digital connectivity are transforming how machine tools operate — from the way parts are designed and programmed to how data flows across production. The combination of AI-driven automation and a digital thread enables faster programming, more accurate simulations, safer workflows, and consistent quality on the shop floor. These developments were explained by […]

Read more →

Managing the Rise of Agentic AI in Manufacturing

During AI Frontiers 2025, participants raised important questions about the growing role of agentic AI in manufacturing—covering topics such as regulation, interoperability, and the management of autonomous systems. While we did not have enough time to address all the questions during the live session, Peter Sorowka, CEO of Cybus, offers in this article a practical direction for […]

Read more →

Embedding AI Agents Into Industrial Data Pipelines: What Manufacturers Should Watch

At Cognite’s 2025 event, Laxmi Akkaraju, SVP Global Services and Solutions, Cognite, spotlighted a new paradigm in industrial AI: agents embedded directly into data workflows, not merely layered on top as analytics. For manufacturers, this shift promises to unlock decisions and use cases that were previously difficult to operationalize reliably — and to do so with […]

Read more →

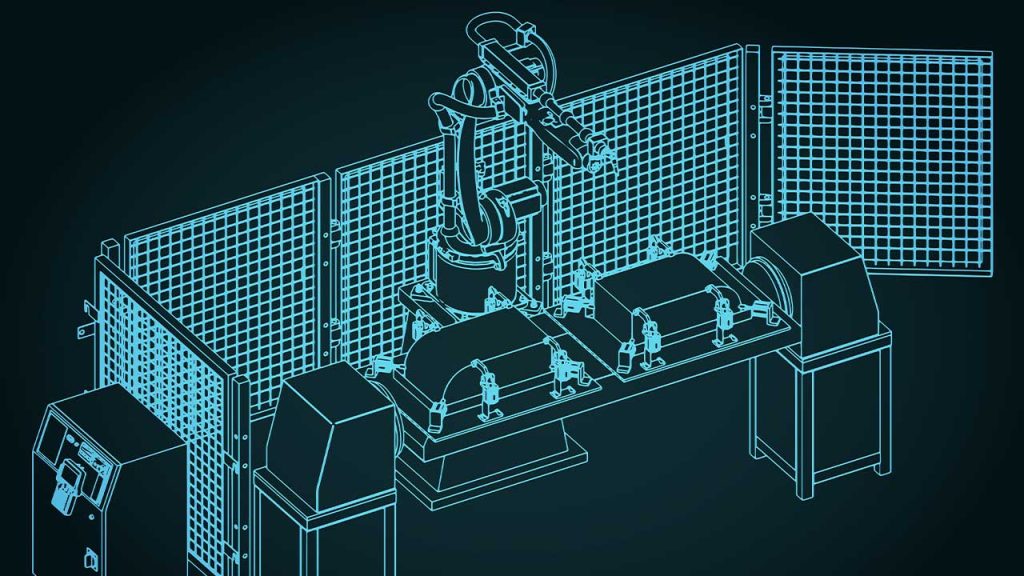

Digital Twins in CNC: From Virtual Proof to Profit

The race in CNC machining is no longer about who has the fastest spindle—it’s about who can validate reality before cutting metal. Across global manufacturing, digital twin technology is emerging as a quiet disruptor, letting engineers simulate machines, verify programs, and train workers in a zero-risk environment.As Siemens’ Dave Morley explained during CXO Insights, digital twins are […]

Read more →

When Machines Negotiate: A New Way to Run Manufacturing

Factories today don’t struggle to collect data — they struggle to make sense of it. Machines measure everything from pressure to vibration, but most of it lacks meaning. Without context, even the most advanced dashboards can’t explain what’s happening on the floor.That’s starting to change.A new generation of AI agents at the edge is learning to understand […]

Read more →