Rethinking Predictive Maintenance: Why the Hardest 10% of Industrial Assets Demand a New Class of Sensors | SPONSORED

Most predictive maintenance sensors work well—until they don’t. When your pump is in an acid-laden environment, your mill bearings hit 120-150°C, or your crane gearbox runs at 4 RPM for half the shift, the majority of “AI-enabled” standard sensors become expensive paperweights.

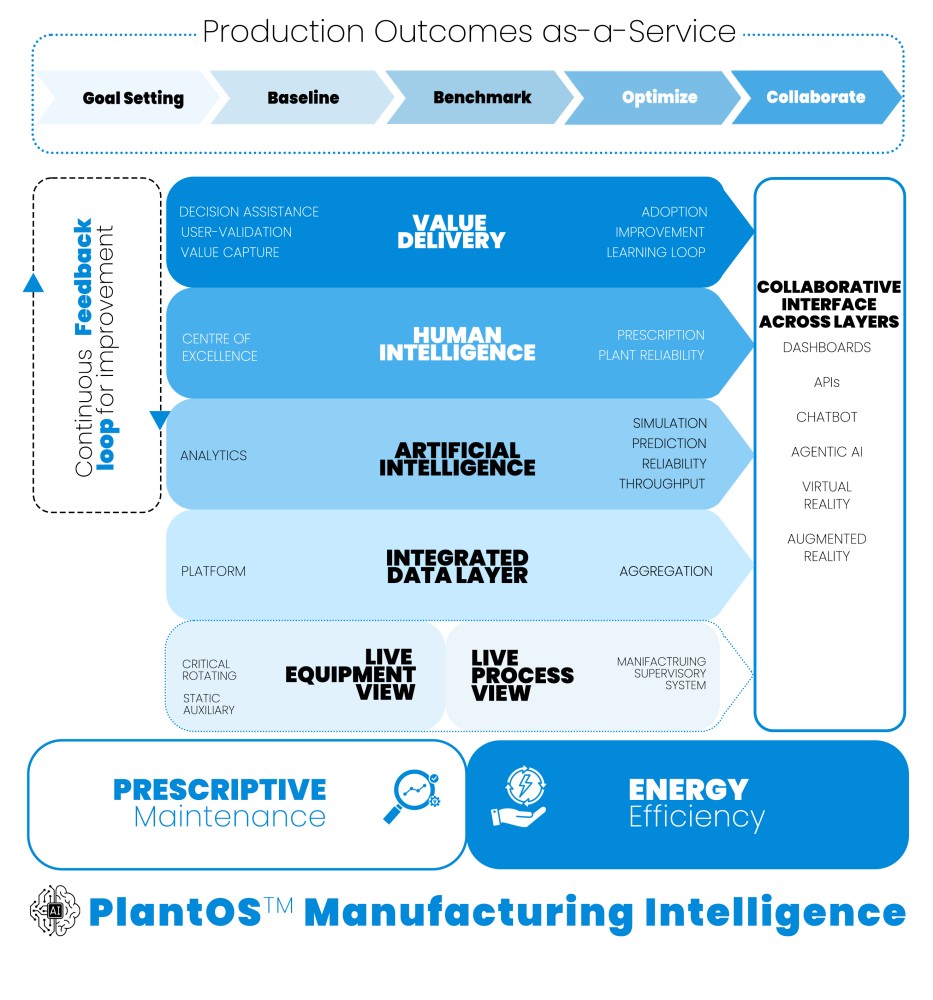

That’s where COOs leading high-reliability plants are quietly shifting from standard predictive AI wireless sensor options to the world’s most compact sensor designed for the harshest process industry equipment, PlantOS Ultra; PlantOS is the world’s most user-validated prescriptive AI platform for process industry outcomes; Because downtime in these environments is measured not in hours, but in millions.

The COO’s Reality

- Downtime costs in steel mills: $15k–$25k/hour

- Batch loss in chemical plants: $250k–$500k in a single upset

- Asset replacement delays in cement & paper: weeks of lost production

In these environments, missing a single fault pattern because your sensor’s bandwidth, temperature rating, or mounting failed… is not an option.

Why Standard Sensors Struggle

- Temperature ceilings – Many can’t exceed 85°C. Bearings, fans, and kiln drives often run hotter.

- Low RPM blind spots – Below 100 RPM, standard FFT-based detection misses developing faults.

- Corrosive and wet environments – Electronics corrode, ingress protection fails, signal noise rises.

- Transient loads – Variable load equipment produces inconsistent vibration signatures that confuse lower-resolution AI models.

PlantOS Ultra: Designed for the Harshest 5% of Assets

- Survives the extremes: Operates from -20°C to 120°C in IP68 SS316 hermetically sealed casing. (can handle up to 150°C for uniaxial variant)

- Sees the invisible: Reads RPMs as low as 35 with integrated magnetic flux sensing—critical for cranes, drum bearings, and slow-rotating kilns. (can handle down to 2.5 RPM)

- True triaxial fidelity: Z-axis to 8kHz and lateral axes to 3kHz—capturing subtle fault harmonics missed by competitors.

- One sensor, three signals: Simultaneous vibration, temperature, and RPM capture for contextual diagnostics.

- Harshest-proof: Extends prescriptive maintenance to even harshest environments where most sensors can’t operate.

Outcome vs. Hype

This isn’t about “AI sensors & dashboards.” It’s about prescriptive AI with advanced sensing technology that delivers User-Validated Outcomes where each second matters.

- Eliminating unplanned downtime with 99.97% accuracy

- Reducing cost of maintenance & energy per unit produced

- Raising productivity, utilization and throughput

- Creating digital ways of working – AI prescribed work orders

- Safeguarding Value Creation per unit time per unit area across steel, cement, metals, chemicals, paper, and energy

COOs Takeaway

If your maintenance program relies on standard sensors, they might be covering 80–90% of your equipment.

But what’s killing your uptime and profit isn’t in the easy 90%. It’s in the hard 10%—the assets that run hot, slow, corrosive, wet, or dangerous.

PlantOS Ultra isn’t just a sensor. It’s the difference between an early fault alert and a seven-figure loss. HERE & NOW!

Hello to User-Validated Outcomes protecting complex critical equipment & process lines!!

Book an outcome session to see how PlantOS can cover your high-risk assets.

About the author

Originally this article was published here and it was written by Kalyan Meduri, the Global Vice President of Marketing & Partnerships at Infinite Uptime, specialized in digital innovation and partnerships. With deep expertise in industrial digitalization, he drives growth through user-validated solutions and is a recognized voice on digital transformation.

Originally this article was published here and it was written by Kalyan Meduri, the Global Vice President of Marketing & Partnerships at Infinite Uptime, specialized in digital innovation and partnerships. With deep expertise in industrial digitalization, he drives growth through user-validated solutions and is a recognized voice on digital transformation.