Why Edge Computing Matters in Manufacturing

Edge computing is not a new concept. When we look back at the history of manufacturing, even during Industry 1.0 and 2.0, decision-making and processes were happening at the edge. It was people at the edge who were making decisions, selling, and producing. With the advent of operational technologies (OT) during Industry 3.0, such as PLCs, sensors, actuators, and time-series databases, edge computing gained even more significance. However, the real game-changer came with the evolution of information technology (IT) and the rise of cloud computing in the 90s and early 2000s.

IT companies like Dell, Siemens, and Rockwell Automation became the premier organizations driving efficiencies, cost savings, and operational improvements in manufacturing through IT infrastructure. Cloud computing also played a significant role in the transformation of the industry. However, with the growing focus on cloud computing, the importance of edge computing took a backseat for some time.

But now, the trend is shifting back towards edge computing. Organizations are realizing that the advantages of edge computing, such as reduced latency, improved data privacy and security, and real-time data processing, are critical for driving operational efficiencies and business growth in the manufacturing industry.

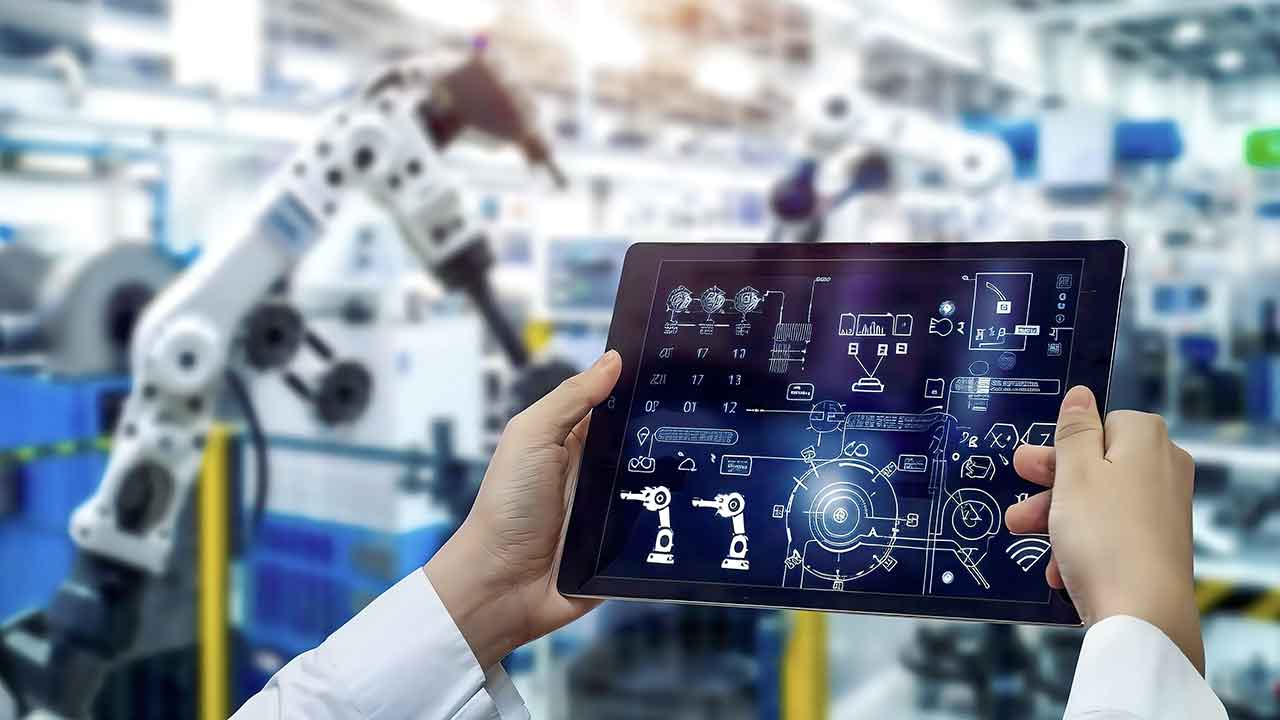

Dell is leveraging edge computing to enable smart manufacturing processes. With edge computing, Dell can process data in real-time at the edge of the network, close to the source of data generation, instead of sending all the data to the cloud for processing. This allows Dell to analyze data faster, make real-time decisions, and drive operational efficiencies in its manufacturing processes.

The appetite for edge computing is growing among companies because they understand the immense potential of edge computing in transforming the manufacturing industry. Edge computing enables organizations to leverage the power of IT and OT convergence, real-time data processing, and advanced analytics to drive efficiencies, reduce costs, and improve business outcomes in manufacturing.

Edge computing is not a new concept, but it is gaining renewed attention in the manufacturing industry. With the evolution of IT and the growing focus on cloud computing in the past, edge computing took a backseat for some time. However, organizations are now realizing the unique advantages of edge computing and its potential in driving operational efficiencies and business growth in the manufacturing sector. Dell, along with other companies, is actively leveraging edge computing to enable smart manufacturing processes and deliver value to its customers. The future of manufacturing is becoming increasingly data-driven, and edge computing is playing a pivotal role in this transformation.

This blog post was created based on the script of the video with the assistance of https://chat.openai.com/.