Two in one fell swoop: The most comprehensive machining Digital Twin | SPONSORED

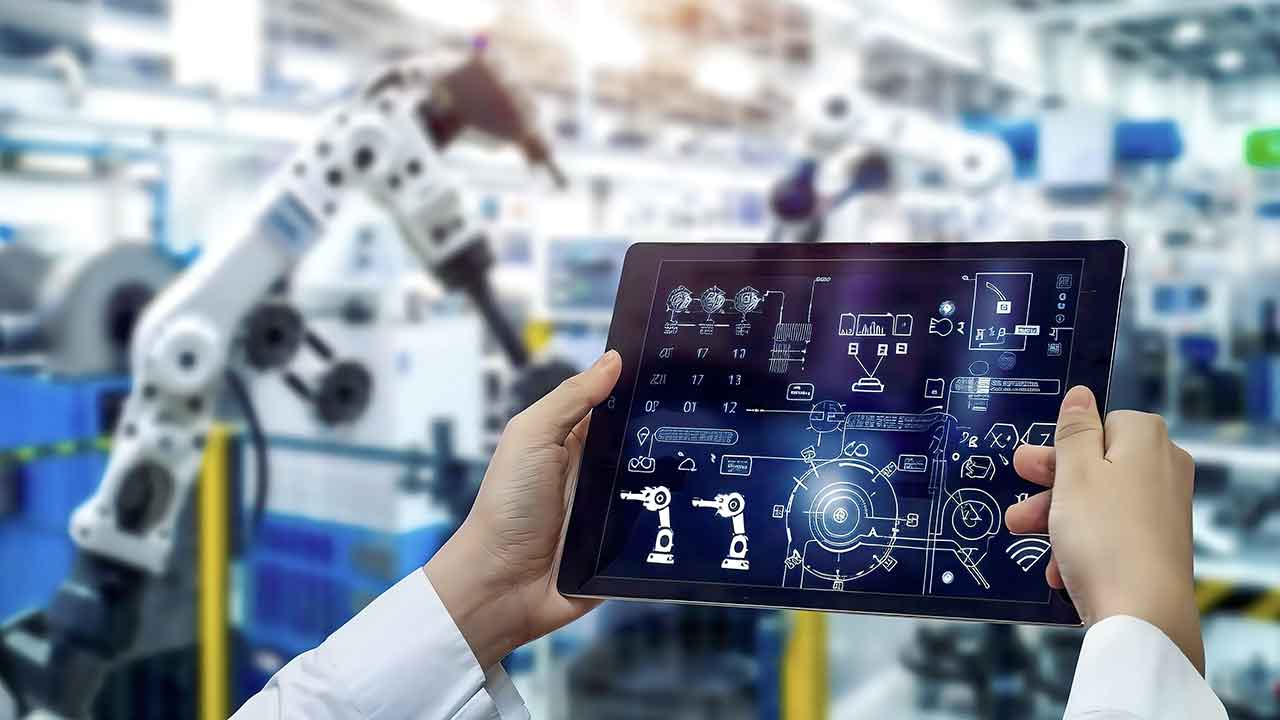

In cooperation with DMG MORI, we will be presenting the most comprehensive machining digital twin at the EMO 2023 trade fair. Using the SINUMERIK ONE, the first digital native CNC, the DMG MORI digital twin visualizes the machine tool, the control, and the workpiece. This software solution is now also available on the Siemens Xcelerator Marketplace.

Anyone who has ever played on a gaming console or run a business simulation will appreciate the advantages of the virtual world. Your strategy didn’t work? You made a wrong decision and are stuck? No problem – mistakes like these can be fixed with a click of the mouse. Just try your luck again – or better: give it another try based on the valuable experience that you were able to acquire without any real-world damage or loss. With this safe way of learning by doing, you can finally overcome obstacles that seemed initially insurmountable on the first attempt.

Financial and ecological challenges

Industrial machining can quickly become expensive – for example, when the milling tool crashes with the workpiece i due to a programming error, when time and money are wasted due to suboptimal NC code, or when the machine is busy performing trial runs instead of producing products.

For the manufacturing industry, which is currently responsible for 20 percent of global CO2-emissions and 30 percent of global energy consumption, the energy transition is another challenge because energy is becoming more and more expensive and the ecological footprint of a product more and more important.

Twins – real and virtual

Here, too, the digital transformation and Industry 4.0 are the key to success. The production machine, a SINUMERIK ONE digital native CNC, has a virtual counterpart on which the programming can be tried out safely and inexpensively while the physical world continues to produce products on the machines.

“Good idea,” you say, “but why isn’t this already a standard feature?” Because it’s easier said than done. After all, the result of a simulation is only as good as the software used to run it. To realistically mirror the real world of manufacturing, the machine tool as well as the control and the workpiece must be mapped down to the smallest detail. Setting up such a digital twin requires not only extensive programming expertise but also plenty of practical experience in all aspects of the production process.

Cooperation between DMG MORI and Siemens

In close cooperation with DMG MORI, one of the world’s leading machine tool manufacturers, we developed the most comprehensive machining Digital Twin based on Siemens Xcelerator – the open digital business platform. This joint offering of the three-fold Digital Twin is now available on Siemens Xcelerator Marketplace.

Faster, safer, and more environmentally friendly

In terms of sustainability, flexibility and time-to-market, such a digital twin is a quantum leap for machining. Programming errors and collisions become immediately visible in the virtual test run and can be corrected before they cause damages of the real machine or scrap workpieces and rework. Production ramp-ups are up to 40 percent faster, which reduces energy consumption significantly.

Because testing and running-in now take place on the DMG MORI Digital Twin, unproductive machine times can be reduced by up to 75 percent. The DMG MORI Digital Twin, available with our SINUMERIK ONE, can also be used to predict the CO2-footprint of the workpiece along the entire value chain, allowing the user to take targeted measures to avoid CO2-emissions long before the first chips fly. More about The Benefits of Using the Digital Twin in Manufacturing

With their partnership on the Siemens Xcelerator platform, global market leaders Siemens and

DMG MORI demonstrate the wide range of opportunities that the joint and consistent use of digitalization offers for productivity and competitiveness. This applies to the users of machines and, in essence, to the manufacturers of machine tools as well. Siemens Xcelerator’s approach of linking different partners in one ecosystem for the benefit of all is impressively demonstrated in Siemens’s partnership with DMG MORI.

More resources: DMG MORI Digital Twin

Sponsored by Siemens