Transition to Industry 4.0 in Three Steps

Whether you’ve embraced the notion of digital manufacturing or you’re wondering where to even begin, there are things you can do right now to move a little closer to the future and make that all-important transition to Industry 4.0.

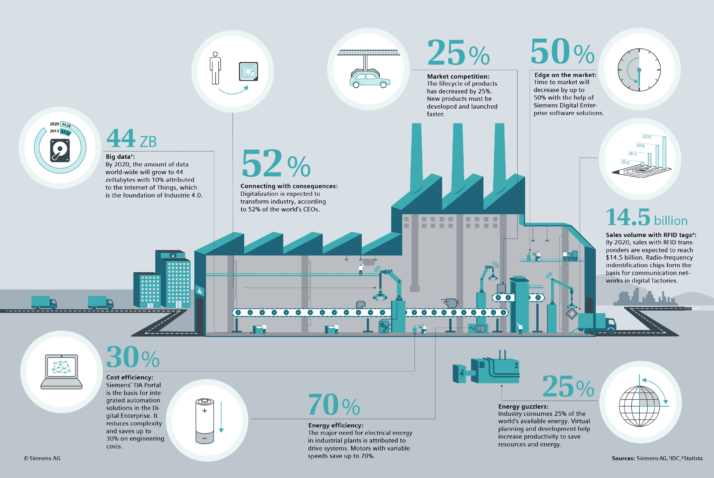

First and foremost, creating networks that can adapt and respond to change will be a vital part of your process if you want to retain success in Industry 4.0. As result of creating sophisticated automated networks, Industrial companies expect to generate 3.6% p.a. in cost reductions over the next five years, driven by internal improvements and by working closely across value chains.

To compete in tomorrow’s world, it’s important to embrace the evolution of technology and understand how to harness its power to enhance your organisation’s operation.

To ensure your processes are at their most efficient, having the ability to incorporate the Internet of Things (IoT) into your everyday operation will prove essential.

As we move deeper into Industry 4.0, the capabilities and tools to help you learn from your products while they’re in the field will be all the more possible meaning you can maximise your output while gaining more time to steer the business towards a bright and prosperous future.

But of course, making the transition to Industry 4.0 can seem easier said than done. If you’re looking to transform your business and embrace this brave new world, here are three steps you can take.

Look to the future

In business, those who look to the future usually become pioneers in their field. You and your business are no exception.

As Industry 4.0 develops, it’s important to understand manufacturing trends, current market trends, innovations and insights in addition to the direction they’re heading in.

Become informed, make plans by collaborating with colleagues, speak to third parties to see what they can offer you, and you’ll be able to strategize with full force. On this occasion, dwelling on the past will prove fruitless.

Understand your pain

When you have a sore knee that won’t go away, to mend it you need to understand the source of the pain in relation to how it’s affecting you.

To gain an insight on what how to improve your operation and understand where to invest in terms of technology, you need to understand the source of your weaknesses. Or more specifically, your organisational pain points.

By using the big data sources to gather as much information about your consumer base, your productivity levels, your output, your profits, and the efficiency of your operation as possible, you’ll be able to make plans to move seamlessly into the realms of Industry 4.0. This will also gain a greater understanding on what isn’t working and which areas need to be fortified.

As a result you’ll be able to refine your plans and build an infrastructure to vastly improve the business, one that incorporates new technologies and ways of thinking.

Locate your pain points, understand why they exist and you’ll be able to eradicate them for good.

Enlist your suppliers

Once you’ve planned for the future, created a strategy, mapped out an infrastructure and decided where as well as how you’re going to invest, you should enlist the help of your suppliers to put everything into practice.

Industry 4.0 is based on cyber-physical systems which marry digital technology and tangible machinery to create one efficient, thriving eco-system.

So, to make your transition final, you’ll need to enlist a host of third party suppliers to make your new set-up and way of working possible.

By now you’ll understand what you want to do, where you want to invest and what you’ll need to make your transition; this means sourcing the right systems, technology and hardware suppliers should be straightforward.

Always speak to potential suppliers in person, taking the time to understand their services and how they can benefit your business. Make decisions at your own pace, weigh up your options and you’ll be up and running to your maximum potential in no time.

Above all else, when you’re making your transition into Industry 4.0 it’s essential that you’re able to plan for potential failures and have the agility to respond to change — keep these things in mind throughout the whole process.

The article was written by Mustapha Zaouini and originally was published here. Mustapha is a Tech Entrepreneur, Investor, Leading Executive specializing in growth strategies & new emerging markets development (Africa & Middle East).

The article was written by Mustapha Zaouini and originally was published here. Mustapha is a Tech Entrepreneur, Investor, Leading Executive specializing in growth strategies & new emerging markets development (Africa & Middle East).