ABB highlights at Hannover Messe 2019 – Day 2

This year at Hannover Messe, ABB is streamlined into four entrepreneurial businesses: Electrification, Industrial Automation, Motion, and Robotics & Discrete Automation.

As our main focus is IIoT, “the factory of the future” is clearly one of the topics we want to know more about. ABB’s “factory of the future” features at Hannover Messe a model production line assembling wristwatch in lot sizes of one, in real time. YuMi collaborative robots offer unmatched precision in assembly operations, while the SuperTrak flexible transport system orchestrates the timely movement of parts from one station to another.

New partnerships were announced, and first joint solutions are showcased.

Here are a few announcements from ABB we found interesting:

Robotics and Discrete Automation

ABB and Ericsson building the “factory of the future”

ABB and Ericsson have strengthened their commitment to accelerate the industrial ecosystem for flexible wireless automation, which will enable enhanced connected services, industrial IoT and artificial intelligence technologies in the future.

The two partners are already fast-tracking the introduction of a new generation of intelligent factory technologies, with Ericsson deploying an intelligent automation system at its manufacturing facilities in Tallinn, Estonia. ABB has provided a fully automated flexible robotics cell solution that assembles 5G radios for Ericsson.

At the Hannover Messe 2019, ABB and Ericsson are showcasing how they are enabling the “factory of the future” with the latest flexible robotics, wireless technologies, 5G, Industrial IoT and motion control technology.

Industrial Automation

The first joint solution of ABB and Dassault Systèmes is showcased at Hannover Messe

The first joint solution of ABB’s landmark global partnership with France’s Dassault Systèmes is showcased at Hannover Messe this year. The scope of this partnership is to offer an end-to-end digital portfolio. This includes an advanced digital twin technology service where customers can test their operations and ABB solutions through virtual representations of factory models and product lines.

Find out more about Modular Automation, a solution for process industries, at ABB’s booth and many more in Hall 11, Stand A35.

Electrification

ABB partners with Rolls-Royce on microgrid solutions

ABB and Rolls-Royce have announced a global partnership on microgrid technology and advanced automation. Together the two companies will offer an innovative, energy-efficient microgrid solution for utilities, commercial and industrial entities.

Microgrids enable resilient power supply even with high penetration of intermittent renewable energy sources like wind and solar. Digital automation and control systems intelligently coordinate distributed energy resources and loads for the microgrid to function efficiently.

Watch our interview with Rob Roys, Regional Sales Manager, ABB, about distributed energy resources technologies ABB is focusing, including microgrids.

In the ABB – Rolls-Royce partnership, ABB Ability™ e-mesh™ solution will provide power generation asset owners a vertically integrated, unified view of their distributed energy resources and renewable power generation that is quick to deploy and that reduce operational costs. Cloud operations, site and fleet optimization, weather and load forecast and machine learning algorithms offer infinite insights for decision-making, such as knowing where to increase investments on maintenance or how to increase revenue streams to operate assets more profitable, and this is how ABB involves in creating sustainable solutions for the future generation.

ABB and MVV – a partnership for a sustainable future

Major German energy service provider MVV has partnered with ABB to launch Energy and Efficiency as a service, with a new full-service solution developed to help industrial and energy companies improve energy efficiency, reduce carbon emissions and lower costs. More details here.

Read also: ABB unveils an asset health solution optimizing switchgear efficiency

Motion

The first Emission-free bus drives visitors at Hannover Messe show

This year, at Hannover Messe, visitors are transported around the site on a new emission-free hybrid shuttle bus, powered by ABB’s high-power chargers. The emission-free autonomy of the Volvo electric-hybrid bus offers a perfect solution for the shorter distances around the site. Combined with ABB fast charging, it offers emission-free transportation all day long.

The high-power 300PD bus charger delivers 300kW of charging power and can recharge a battery in three to six minutes. It is based on OppCharge, a concept for electric bus charging with direct current using a pantograph mounted on the infrastructure for end point charging. This allows buses to be charged at the end of the line, without impacting on the normal operation of the route.

The Hannover Messe project comes a year after ABB was commissioned to supply its high-power 200P chargers to charge the city of Goettingen’s public bus transport system, which uses three Volvo electric hybrid buses to transport more than 50 000 passengers every day. More about ABB’s e-mobility projects here.

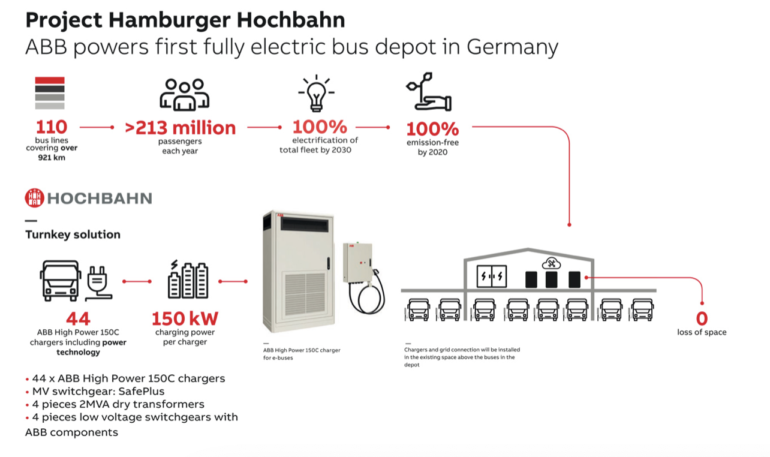

Today ABB also announced that Hamburger Hochbahn AG has appointed ABB to supply infrastructure for 44 high-power chargers, for Germany’s first electric bus depot.

More about ABB’s product innovations and highlights here.

Disclosure: We collaborate with ABB Industrial Automation Energy Industries Division (US branch), running an awareness campaign and preparing a lead generation one in the upcoming months. This article is NOT part of any of these two campaigns and it represents our selection of the announcements that caught our attention. Stay tuned for more insights, interviews, and comments directly from Hannover Messe 2019.

This article was written by Carolina Rudinschi, Ph.D., the co-founder of IIoT World.