Agentic AI and IIoT: Complex Questions and Expert Perspectives

At AI Frontiers, the panel on Agentic AI & Integrated Data Workflows generated more questions than could be answered live. To continue the discussion, Andrew Scheuermann, CEO of Arch Systems, recorded a series of short video…

Can the Asset Administrative Shell Make Factory Data AI-Ready?

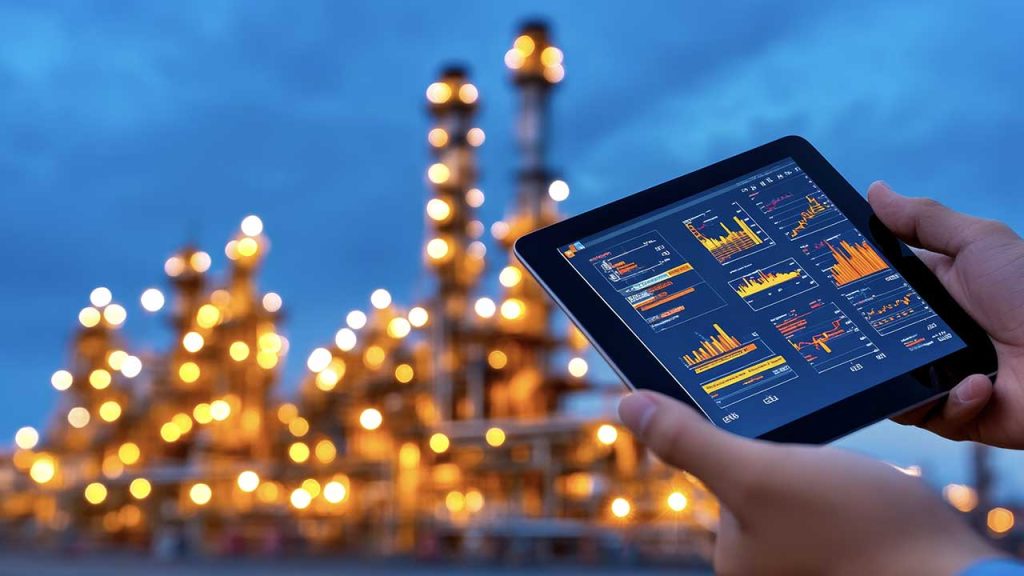

Most factories already collect oceans of data, yet too much of it arrives in different shapes, names, and units. That inconsistency slows down Artificial Intelligence (AI) projects more than any model choice. During AI Frontiers 2025,…

Agentic AI in manufacturing does not need to begin with a moonshot

Walk any production line and you’ll see the same truth: decisions live on the human–machine interfaces (HMIs) that operators watch all day. If you want agentic AI to help now—not after a multiyear overhaul—start there. Let…

How Much Prep Work Do Trusted AI Agents Really Need on the Factory Floor?

Picture a line drifting off spec at midnight. Operators don’t want a chatbot—they need a system that notices the issue, understands the context, and recommends an action they can trust. That trust isn’t created at the…

Digital Transformation for Manufacturers: Why Small Firms Can’t Wait

When people hear “digital transformation,” many picture massive factories with endless budgets and global IT teams. But the reality is that the future of U.S. manufacturing depends on much smaller companies. According to the SBA, nearly…

Who Should Own an AI Pilot in Manufacturing?

Answering an AI Frontiers 2025 audience questionContext. During AI Frontiers 2025, an attendee asked: Who should be the business owner and senior stakeholder for an AI proof of concept—and how should it be structured for quick wins and long-term…

From Paper to Pixels: Why Sheet Metal Fabrication Needs a Digital Traveller

Walk into many sheet metal shops today, and you’ll still find one of the most critical workflows running on a surprisingly fragile medium: paper. Job travellers, or the packets of instructions that follow a part from…

Can SMEs Afford Agentic AI?

Small and mid-size manufacturers often ask: Is agentic AI truly within our reach, or is it a luxury only global plants can afford? At the “Agentic AI in Manufacturing: From Copilots to Autonomous Systems” session during AI Frontiers…

From Industrial Automation to Industrial Autonomy: Yokogawa’s IA2IA Journey

In the conversation, Nick Clark from Yokogawa laid out what the transition from Industrial Automation to Industrial Autonomy — IA2IA — really means. Industrial automation has long been about predefined processes and protocols. Plants and systems…

Agentic AI in Manufacturing: Best Practices for Quality, Speed, and Safety

Answering the audience’s questions At the AI Frontiers 2025 event, one audience member posed a question that goes to the heart of modern manufacturing challenges: “When introducing agentic AI into domain-specific workflows, what best practices help manufacturers improve…