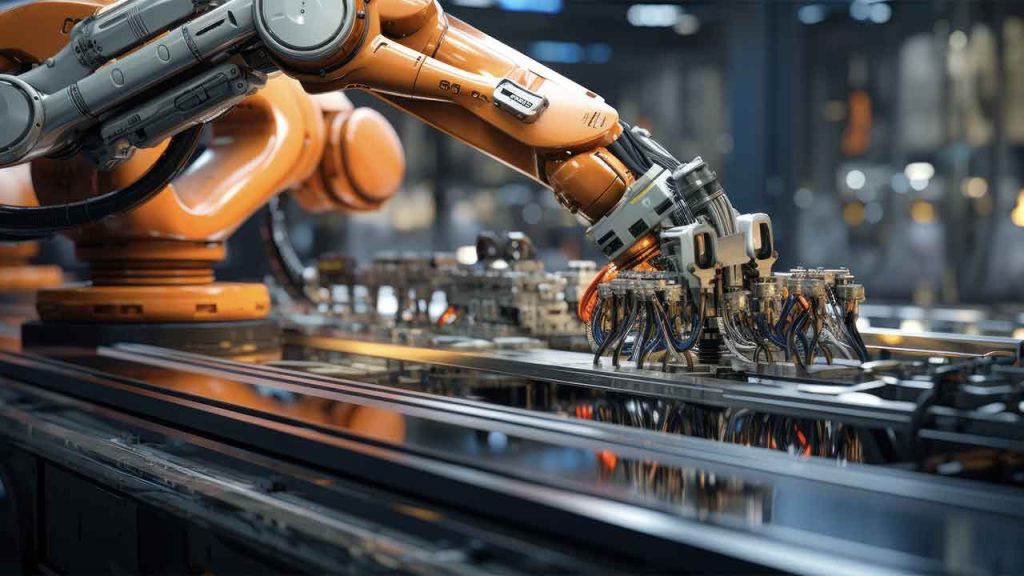

IIoT and ML: The Secret to Reducing Waste and Maximizing ROI in Manufacturing

For modern manufacturers to stay relevant in an ever-expanding global market, they have to overcome a plethora of challenges that demand innovative solutions. Rising costs of raw materials and energy have placed considerable strain on profit margins, causing manufacturers to adopt more cost-efficient strategies. Concurrently, there is an increasing emphasis on sustainable practices that minimize […]

Read more →