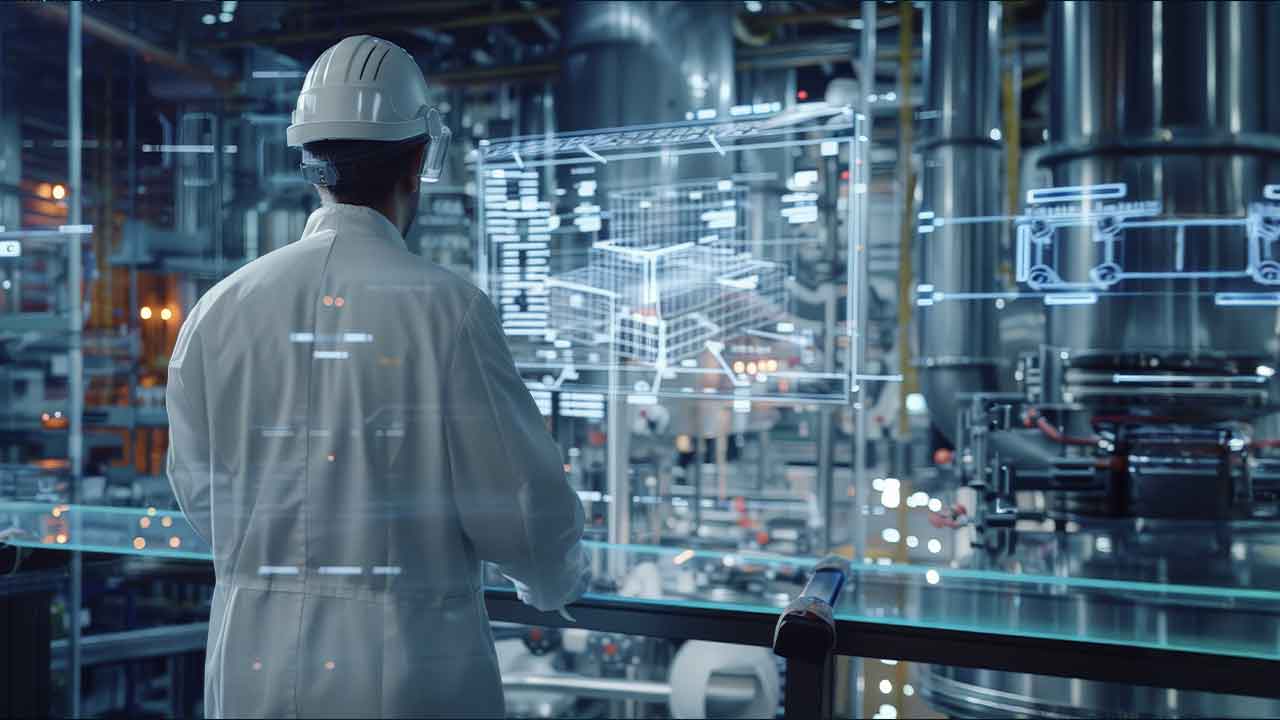

From Data to Insights: Turning Industrial Data into Actionable Intelligence

Modern industrial operations are redefining their relationship with data. No longer just a historical record, data now shapes real-time decisions and future outcomes. Systems across the factory floor continuously collect temperature, vibration, and motor speed readings through PLCs, IoT devices,

InfluxDB 3: Turning Industrial Data into Real-Time Action with Less Complexity

For manufacturers, utilities, and other industrial operators, time series data—information captured over time from machines, sensors, and control systems—is the backbone of modern operations. But as data volumes grow, many organizations are still struggling to keep up: storing the data

[Booklet] Manufacturing at the Crossroads 2025: Real-World Lessons from Industrial Leaders

What does it take to make digital transformation stick—beyond pilots, platforms, and buzzwords? At Hannover Messe 2025, the conversation around industrial transformation reached a new level of clarity—and urgency. From AI and agentic automation to modular MES platforms and resilient supply

How Data is Rebuilding Manufacturing from the Edge Up

An industry conversation with Pugal Janakiraman, Global Manufacturing CTO at Snowflake, and Evan Kaplan, CEO of InfluxData. Manufacturing's Data Mindset Is Changing Manufacturers have long relied on data to understand what went wrong—after the fact. When a production line stalled, or equipment

What’s Changing in Industrial Data Management: Key Takeaways from Hannover Messe 2025

At Hannover Messe 2025, InfluxData CEO Evan Kaplan and HighByte CPO John Harrington discuss how manufacturers are shifting from data collection to data intelligence and what’s required to support that transformation. Below are the most important insights that emerged from

The Role of Predictive Maintenance in Achieving World-Class OEE with IIoT

OEE (overall equipment effectiveness) is a productivity and performance metric that helps find new inefficiencies and unlock the full potential of manufacturing. OEE helps manufacturers understand how well a machine, a manufacturing process, or a line is running, as well

[New booklet] How IIoT and AI Are Driving Smarter Operational Investments

In today’s rapidly evolving industrial landscape, staying competitive means being smart with your operations — and smarter with your investments. Leading organizations are turning to the Industrial Internet of Things (IIoT) and Artificial Intelligence (AI) to optimize processes, cut costs, and boost ROI. This new

The Business Case for IIoT in Manufacturing: Proving ROI with Real-Time Data

The Industrial Internet of Things (IIoT) is transforming modern manufacturing by enabling connected, data-driven processes that improve efficiency, reduce downtime, and enhance decision-making. Manufacturers increasingly rely on IIoT to optimize production, but proving its return on investment (ROI) remains a

Are data historians holding us back?

The role of the data historian has changed a lot since the 1980s, and it’s time to rethink how it serves us. Industry 4.0 demands better integration between OT and IT systems, allowing teams to centralize data and extract real-time