Artificial intelligence and digital connectivity are transforming how machine tools operate — from the way parts are designed and programmed to how data flows across production. The combination of AI-driven automation and a digital thread enables faster programming, more accurate simulations, safer workflows, and consistent quality on the shop floor. These developments were explained by Franziska Trautmann, Business Development Manager for Digitalization – Machine Tool Systems at Siemens AG, in a recent CXO Insights discussion.

AI across the production workflow

AI supports several stages of the machining process.

In design, it accelerates generative design and improves simulation accuracy, helping engineers create complex and lightweight structures more quickly.

In planning, AI-generated 3D human models simulate operator movements and postures, improving workflow efficiency and workplace safety.

In programming, AI identifies geometric features of a part and suggests machining strategies, operations, and tools. This allows complex CNC programs to be created faster and reduces manual programming time.

The function of the digital thread

The digital thread connects design, planning, and manufacturing in one data backbone, ensuring consistent and traceable information throughout the process.

Data generated during design, such as product manufacturing information, can be reused later to support quality assurance.

Manufacturing and assembly data feed into manufacturing operations management systems, providing insights that help improve efficiency.

Information from the programming phase is transferred directly to the shop floor to start real production without manual data re-entry or duplication.

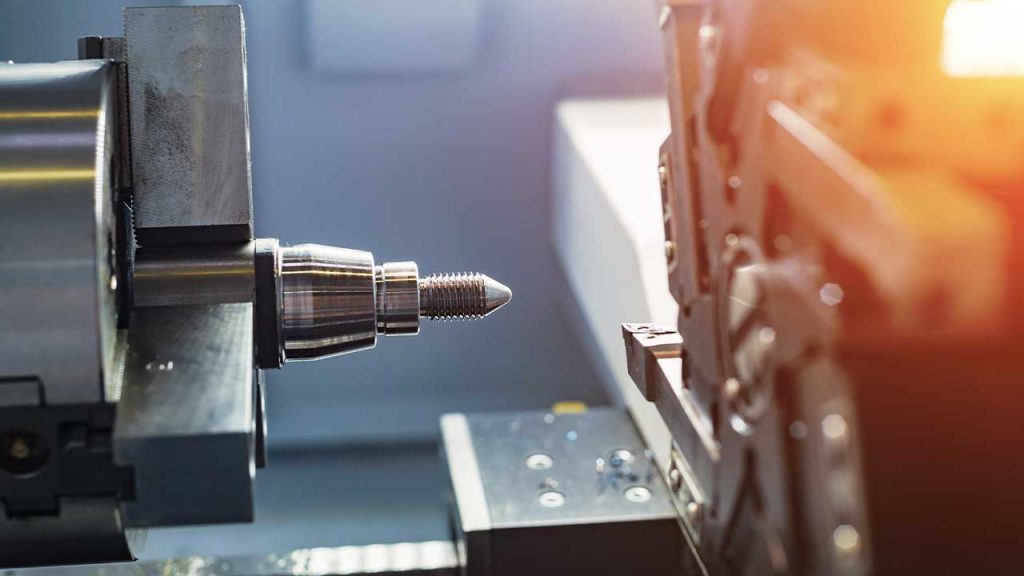

Combining additive and CNC machining

Additive manufacturing and CNC machining each offer distinct advantages. Additive methods enable the creation of complex, lightweight parts with minimal material waste, while CNC ensures the precision and surface quality required in industries such as aerospace. When combined, they merge design flexibility with the high accuracy needed for final production.

Impact for end users

The integration of AI and the digital thread simplifies every stage of machining. It shortens design and programming time, improves safety, and strengthens the link between engineering and production. For manufacturers, these technologies turn disconnected steps into a continuous, data-driven process — improving overall reliability and efficiency in machine tool operations.

Related articles: