[Use case] Improve Robotic Welding Performance Using Real-Time Monitoring System | SPONSORED

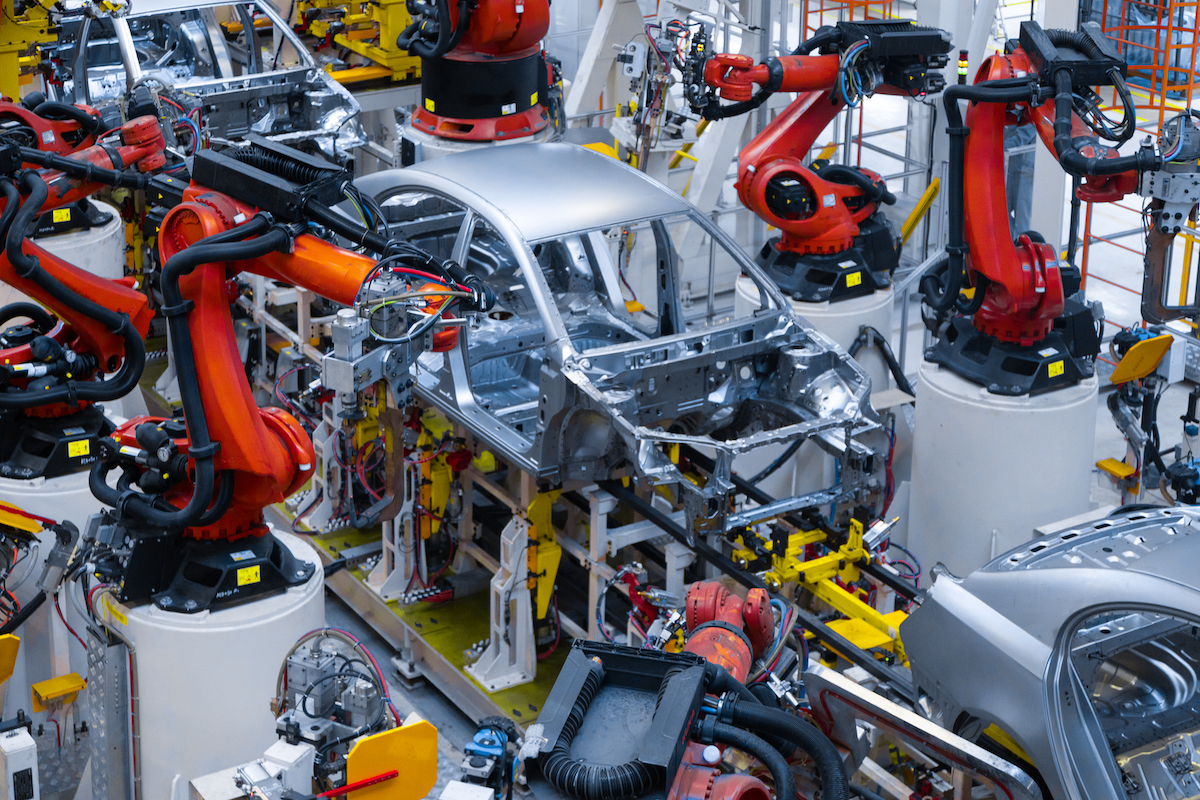

A large manufacturer produces hundreds of parts for an industrial distributor of multiple vehicle types.

Challenges

- Throughout the plant, automated robotic welding systems are utilized. The motor supplying wire feed to the welding gun often wears.

- Irregular wire feeding causes the wire to buckle and jam. This means unplanned stoppages and downtime of the welding cell, resulting in significant costs.

- Today’s transducers used for controlling the welding motor current, provide no warning of over-draw or under-draw current, which is the underlying cause of jams and uneven wire feed.

Find out how ifm’s moneo Real-Time Monitoring System improves robot welding performance by monitoring the current of weld feed speed to the welding gun. Overload and underload spikes are identified and allows the operator the opportunity to correct the wire feed for uninterrupted production.

Read the full use case here.

Sponsored by ifm