Graphite Energy: Powering Decarbonization and Digital Twins with InfluxDB

A significant obstacle to achieving industrial heat decarbonization is transforming renewable energy from inconsistent to dependable, as manufacturing facilities demand. While solar panels produce power only during daylight hours and wind turbines rely on windy conditions, industrial operations require a continuous and stable energy supply. Graphite Energy, an Australian company, identified this disparity and embarked on developing a remedy for it.

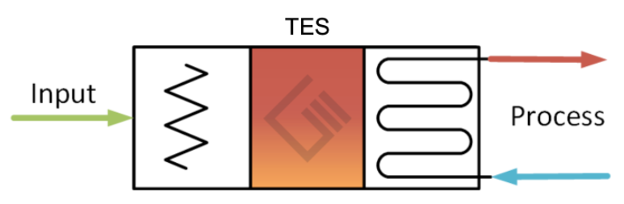

The company created Thermal Energy Storage (TES) units to assist in balancing the distribution of energy from sustainable sources. These TES units aim to increase the accessibility of renewable energy, thereby reducing manufacturers’ dependence on non-renewable fuels and promoting the decarbonization of industries.

TES units produce heat or steam to support industrial processes, allowing organizations to decouple renewable energy from the direct energy needs on the factory floor.

TES units contain monitoring technology and record almost every detail. Each unit captures hundreds of datasets, resulting in around 1 million data points daily. Graphite Energy collects this data on the device and in the cloud, storing it in InfluxDB Cloud, a platform specifically designed for time series data. The units utilize various cloud-based and edge-compute analytics, which are then displayed in real-time through web-based dashboards.

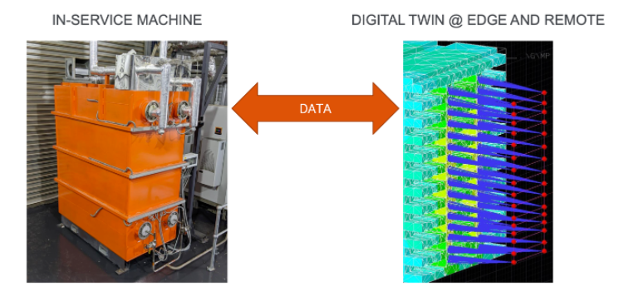

Graphite Energy relies heavily on this data collection and analysis because it’s mission-critical. By using a data-driven approach, they can remotely monitor and improve the performance of their devices in the field. Graphite Energy utilizes a Node-RED workflow to manage its data, which involves using Smartsheet to obtain configuration information, collecting data from TES devices through Node-RED, and processing and engineering the data with tools like Python and C# before storing it in InfluxDB. Once the data is in InfluxDB, Graphite Energy’s engineers query and transform that data to feed their digital twin feature.

Graphite Energy’s process of managing time series data leads to the creation of a digital twin, which is a virtual representation of a TES unit. This model closely mirrors the actual performance of the machine, with an accuracy of approximately 5 percent. The digital twin not only allows Graphite Energy to both look ahead and review past performance but also serves as a powerful tool for predicting and enhancing production, thereby delivering significant benefits.

Source: Graphite Energy

Graphite Energy is making significant headway in reducing industrial carbon emissions and promoting the effective use of renewable energy by utilizing connected TES devices, analyzing data, and implementing digital twins.

To learn more about how Graphite Energy uses InfluxDB, check out the full case study.