Collaborative Operations Center – what it means for utilities in the digital transformation process

Last month, together with my business partner in IIoT World, Carolina Rudinschi, PhD, I attended the opening of ABB’s latest Global Collaborative Operations Center in Genoa, Italy, an event that brought together 30+ analysts and 50+ customers from all over the world. The program included a live demo of the inaugural center’s capabilities, presentations by ABB’s key Digital leadership and several customers.

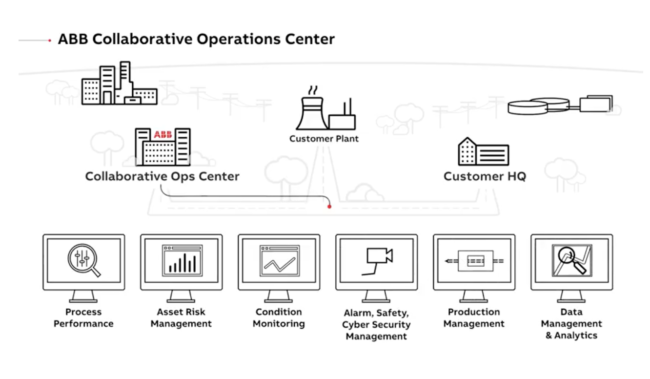

Collaborative Operations provides performance optimization, remote monitoring and preventive analysis technologies to ensure industrial cybersecurity, improve efficiency and energy optimization in power generation and water industries among other.

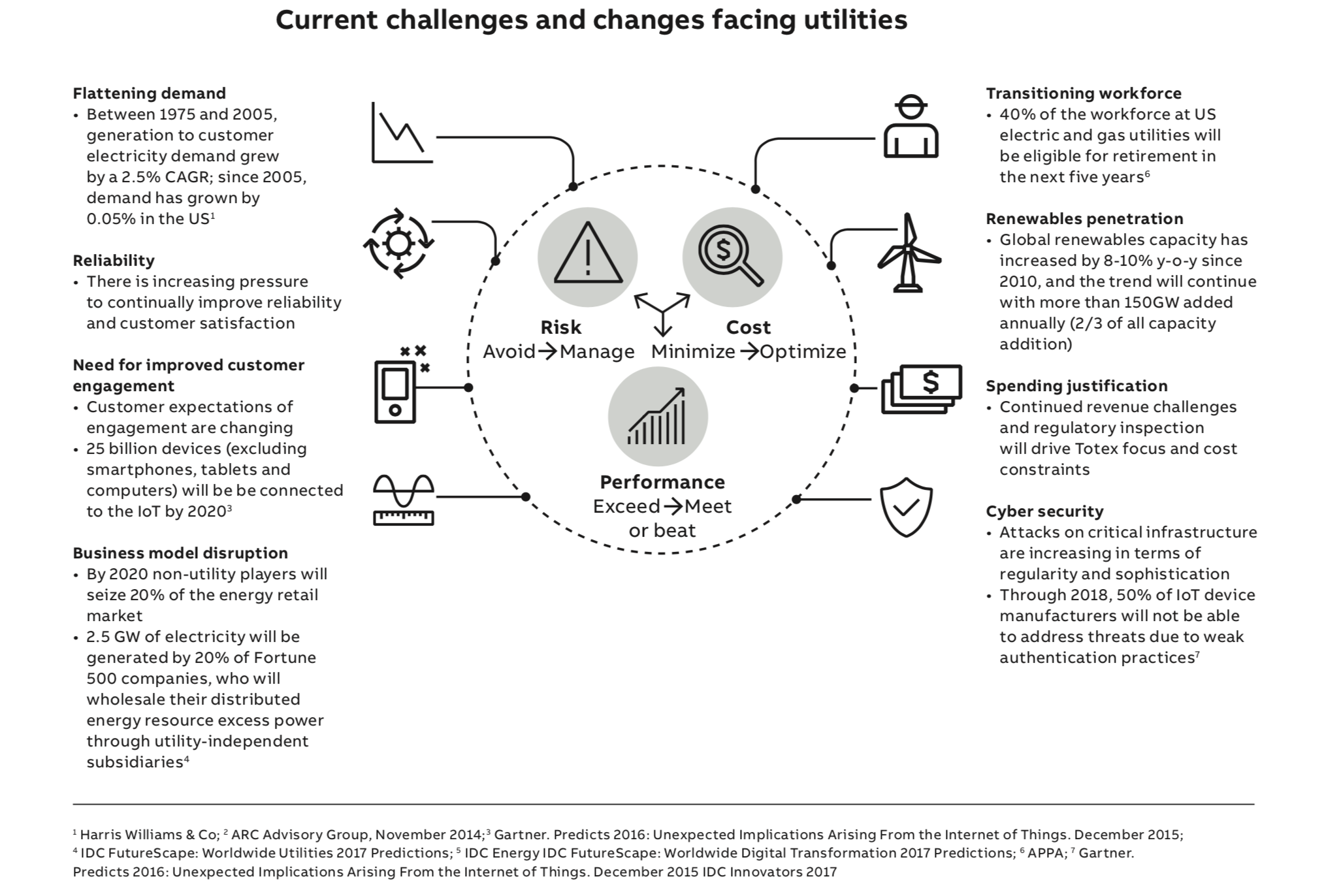

Challenges

For more than 25 years utilities and energy companies have faced more and bigger challenges than perhaps any other industry. Deregulation and power trading, competition and price volatility, compliance with emissions control, the influx of variable renewables into the energy mix, flexible production instead of constant operation at base load, a generation of highly skilled people entering retirement, and the threat to plants and data of cyberattack – are among the most crucial.

So, what is the solution to this stream of disruptions to traditional business models? And how can utility companies best manage digital transformation risk, minimize costs and optimize plant and fleet performance?

Further reading: Biggest Challenges Facing Water Industry

The solution: Digitalization and Collaborative Operations

According to an article published by Deloitte in 2016: “utilities have been able to invest heavily in generation and delivery infrastructure because steady growth in demand maintained affordable prices for customers and yielded reasonable returns. However, increased efficiency, conservation efforts, and alternative power sources have eroded demand growth from about 7 percent annually (1949 to 1973) to about 2.5 percent (1974 to 2013); the projected growth from now until 2040 is less than 1 percent.”

According to the same paper published by Deloitte: “IoT can improve the efficiency and performance of the power grid in three phases: first, by gathering data from sensors to improve the resilience of the grid; then through enablement, where utilities use that data to actively manage resources; and finally, optimization, where all stakeholders are able to make informed decisions about power usage and generation. Through these three phases, IoT offers some indications of how utilities can not only survive, but thrive, in this new competitive environment.”

In this case, ABB is facilitating optimization through its new collaborative operations center in Genoa and others around the globe using specialists in machine learning, data analytics, AR, etc., all of them concentrated in one place.

In this new era of digitization, close collaboration between partners is vital to reap the full benefits that big data and analytics offer.

From reactive to a predictive maintenance perspective

What does Collaborative Operations Center mean? Susan Peterson explains: it comprises a comprehensive range of digital capabilities and services that improve operational efficiency through Operational support, Analytics, Predictive maintenance, Optimization, Industrial Cybersecurity, safety and Control.

What do these capabilities and services meant to the utilities companies:

Operational support is via a cyber-secure, high-speed connection to the fleet of plants to make Collaborative Operations possible. It includes new technologies like Microsoft HoloLens to make troubleshooting fast, efficient and economical.

Analytics visualizes and interprets the data provided by algorithms, turning it into easy-to-read dashboards on plant and fleet key performance indicators to support management and Operations and Maintenance personnel. Analytics also simulates plant behavior to train staff how to handle critical events before they happen.

Predictive maintenance applications monitor and analyze vibration, temperature and other variables to understand machine behavior, identify potential problems, pinpoint the root cause and predict when maintenance is required.

Optimization incorporates a large range of applications to improve asset performance and optimize operations, including emissions monitoring, energy optimization, performance optimization and alarm management.

Industrial Cyber security and safety

Provides protection and continuously monitor cybersecurity to ensure that the DCS continuously follows settings and best practices. In safety, the centers enables solutions that digitalize hazard and near-miss reporting, making it faster and easier to report incidents, analyze the data and improve safety.

Control

Offers expertise in plant and process hardware and software and customers set up and operate their remote-control center for fleet operations.

Collaborative Operations Benefits

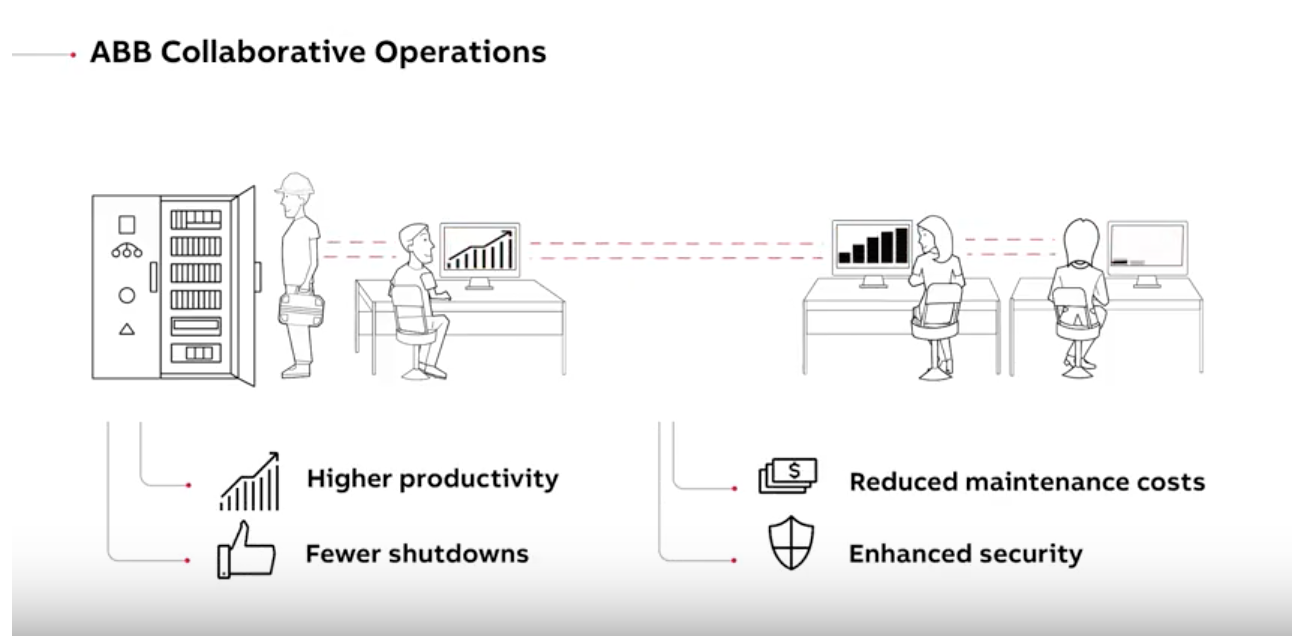

What outcomes should utilities companies expect?

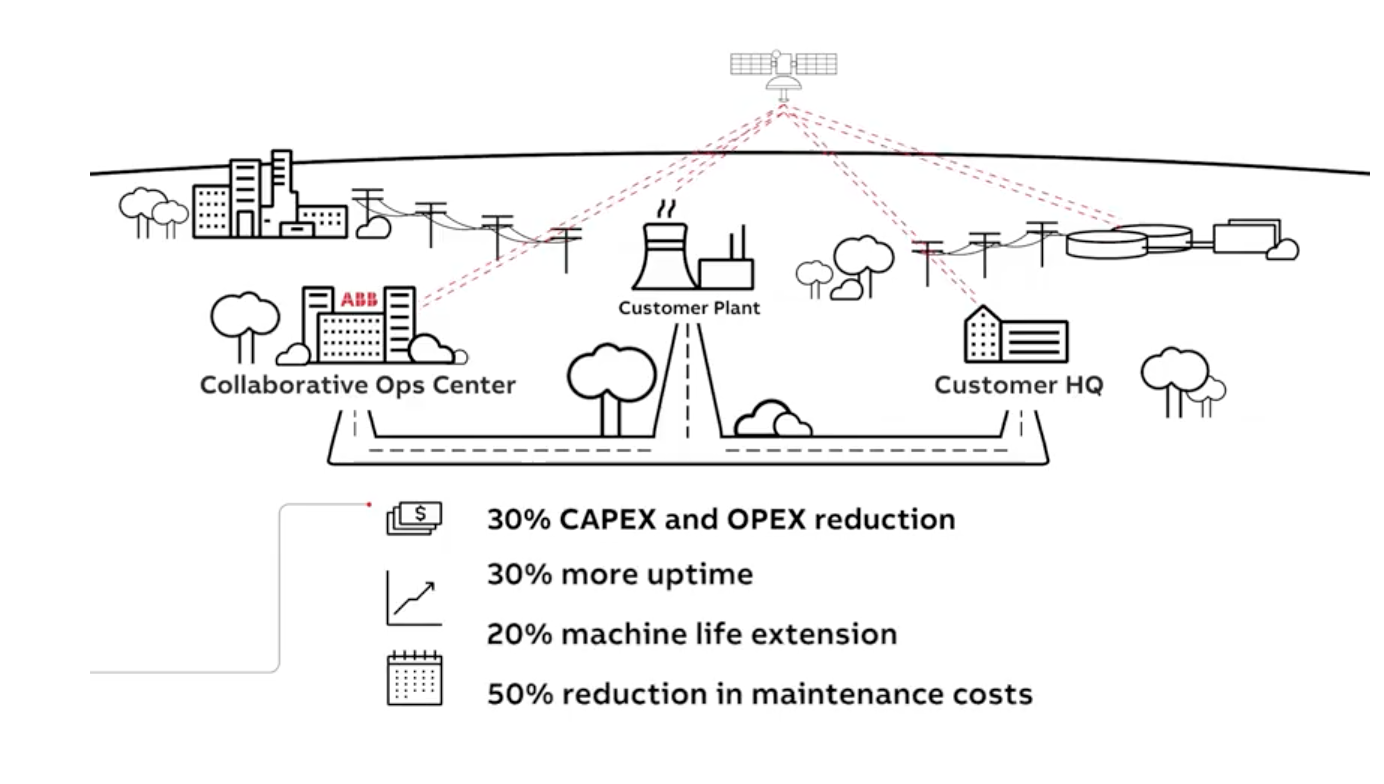

ABB Ability Collaborative Operations uses data to provide more value to customers through information analytics, making this data more useful for driving decisions that optimize plant and fleet performance. Collaborative Operations is proven to provide:

– 20% extension of machine life by using immediate data analysis to better manage assets, processes and risks

– 50% reduction in maintenance costs by using predictive rather than preventive and reactive maintenance practices

– deeper visibility into equipment, plant and fleet performance, enabling customers to better understand performance capability and operating boundaries. Source: ABB.com

Final remarks

Final remarks

Vertical Go To Market approach: While some of the big companies focus on technology and positioned their Industrial IoT Platforms horizontal (a platform for all of their business needs), ABB’s vertical approach aligns their resources based in the industry to better serve their customers and focuses on business outcomes (vs technology).

Partner ecosystem: ABB has fewer partnerships than most of the other IIoT platform providers (like GE etc); they found synergies with companies like Microsoft (cloud services), IBM Watson (AI), HPE, SAP (big-data query) and a few domain specialists.

For more details watch this short presentation movie, check ABB’s Collaborative Operations Center website or watch some of our live tweets from the event: