In most plants, data visibility has improved dramatically. Modern time series databases connect seamlessly with SCADA systems, historians, and operational dashboards, giving teams real-time insight into production. This foundational layer—basic monitoring—has become table stakes in manufacturing.

But visibility alone isn’t enough. According to a study by Aberdeen Research, unplanned downtime in manufacturing can cost up to a massive $260,000 per hour. Manufacturers need to anticipate what’s coming next and act before problems escalate into failures.

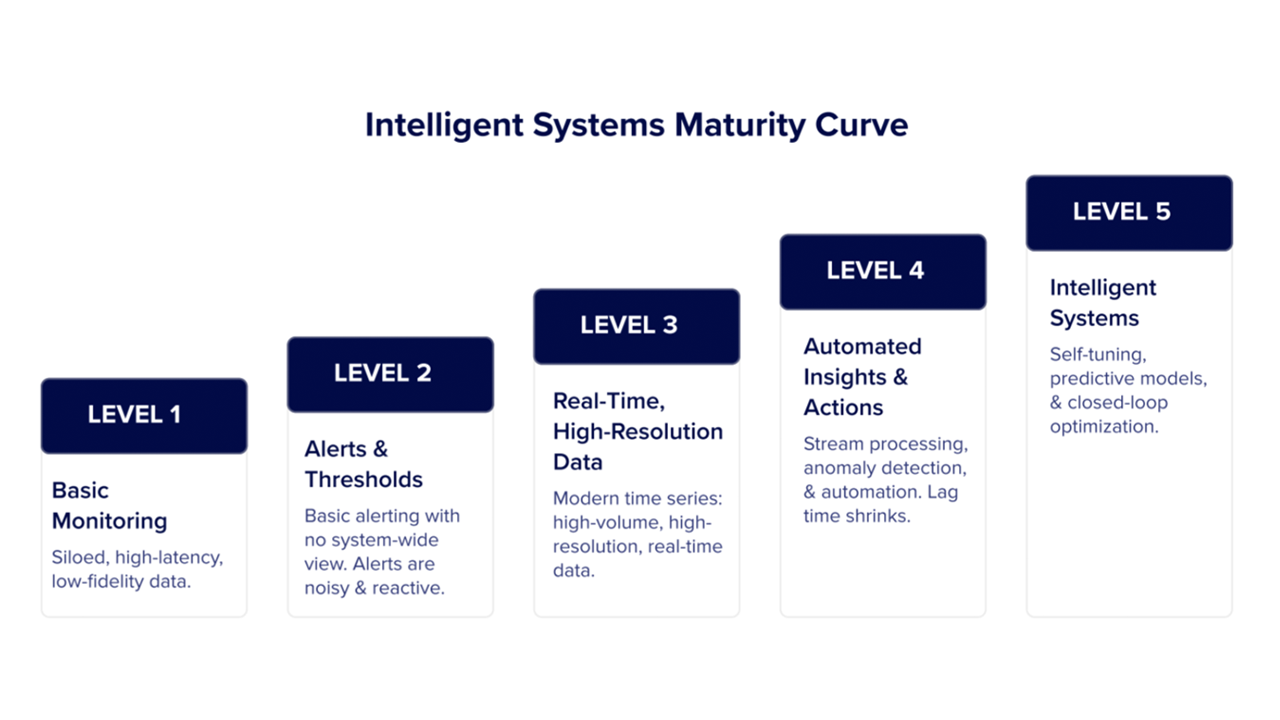

The Maturity Journey: From Monitoring to Prevention

The Intelligent Systems Maturity Model maps the path from reactive monitoring to intelligent, self-optimizing systems:

- Level 1: Basic Monitoring — Siloed, high-latency, low-fidelity data.

- Level 2: Alerts & Thresholds — Basic alerting with no system-wide view; alerts are noisy and reactive.

- Level 3: Real-Time, High-Resolution Data — Modern time series: high-volume, high-resolution, real-time data.

- Level 4: Automated Insights & Actions — Stream processing, anomaly detection, and automation; lag time shrinks.

- Level 5: Intelligent Systems — Self-tuning, predictive models, and closed-loop optimization.

Most manufacturers operate between Level 2 and Level 3. They can see what’s happening, but they’re still reacting to problems rather than preventing them.

Moving to Predictive Maintenance

Predictive maintenance represents Level 4 maturity in action. Instead of waiting for dashboards to refresh, systems continuously analyze sensor data in motion, detecting shifts in vibration, temperature, or current that signal impending failure. A temperature spike paired with batch number, production line ID, and environmental readings reveals root causes in real time.

This shift—from passive dashboards to active insight—turns manufacturing from reactive responses into continuous prevention.

Why It Matters Now

Manufacturers face rising pressure from energy costs, supply chain volatility, and talent shortages. They cannot afford inefficiencies caused by delayed responses. Real-time architectures don’t just make operations faster; they make them safer, more resilient, and more competitive. Instead of merely logging history, data becomes a living tool for foresight.

Source: “Predict, Prevent, Optimize: Real Results from Augmented Industrial Data” session, AI Frontiers 2025 event.