Deploying Analytics On The Shop Floor: How And Where To Start

Industrial Digital Transformation is happening, but the reality is that most companies are handling data on paper. To think about analytics on the shop floor, one of the first things to be done is to automate not only the…

Smart Manufacturing: A Machine Monitoring Success Story

When pen-and-paper methods of tracking job efficiency left AccuRounds’ engineers and managers in the dark, the shop switched machine monitoring system. However, this brought morale challenges along with it. The data-driven practice quickly demonstrated the benefits…

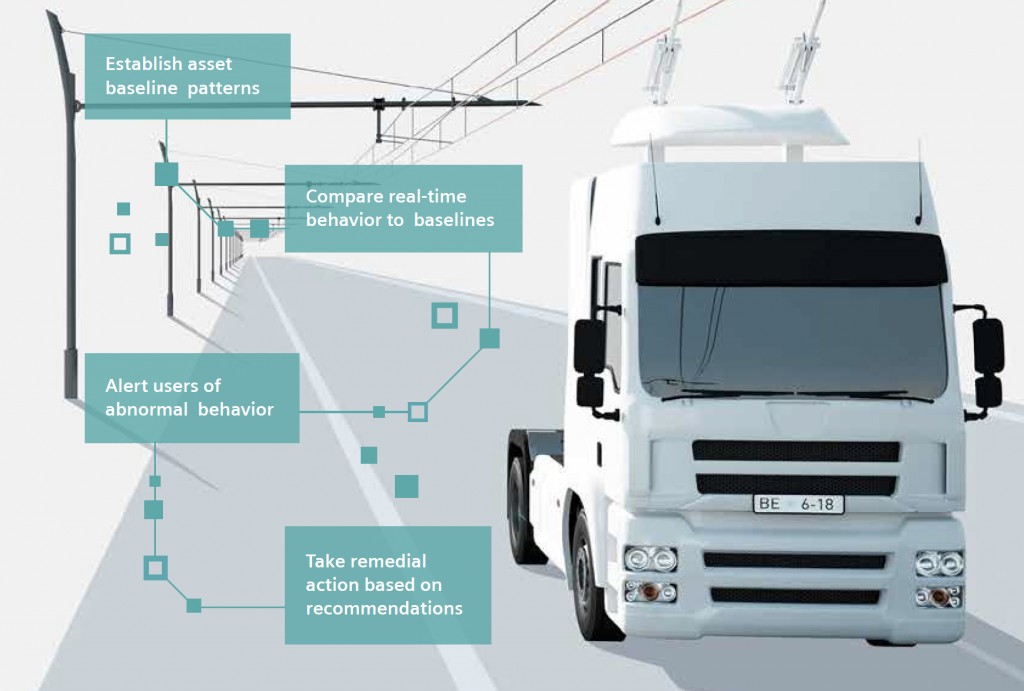

How to Minimize Asset Failure with Predictive Maintenance

Existing maintenance solutions limit production. With the legacy tools and processes at their disposal, manufacturers commonly take reactive or scheduled maintenance approaches that present a multitude of challenges: Existing Maintenance approaches are costly: Up to $1.3M per hour…

Six Steps to Predictive Maintenance

The manufacturing sector is facing a myriad of challenges, but they all point in one direction – improving the bottom-line performance. Within the energy sector, one of the most important drivers is to increase operational efficiency.…

Maintaining Factory Efficiency in a Crisis through Remote Monitoring

The World Health Organization’s (WHO) announcement about Covid – 19 reaching pandemic levels triggered responses across the industrial world. In industrial manufacturing, shop floor activity hit its lowest levels since the Second World War and in…

7 Business Reasons to Develop a Predictive Maintenance Program

Predictive Maintenance allows you to offer new services to customers, where you use realtime data and insights from your deployed base of units to distance yourself from the competition and create enhanced customer value. Predictive Maintenance…

How IoT Supported Maintenance Improves Product Quality

The number of possible applications of IIoT grows every day, and this trend isn’t likely to change anytime soon. The latest numbers estimate that the combined IoT markets will reach a staggering $520B by 2021. An…

Real-Time Data for Real-World Decisions

Manufacturing relies on continuous production. Fast, accurate, real-time analytical insights are intuitively recognized as valuable. Many decisions must be made in real-time, so having real-time data will naturally improve those decisions. Actionable, up-to-date metrics create many…

How to Capture the Right Type of Data

When it comes to collecting data with industrial IoT within the world of manufacturing, it isn’t just about quantity. It’s also about the quality of the information that you are gathering from various machines; manufacturing data…

Remote Machine Monitoring: A Game-Changer for Machine Builders

An issue in manufacturing that is singular to machine builders is the speed with which they can respond with service to the machines, in the case of a failure. In the past, this has usually meant…