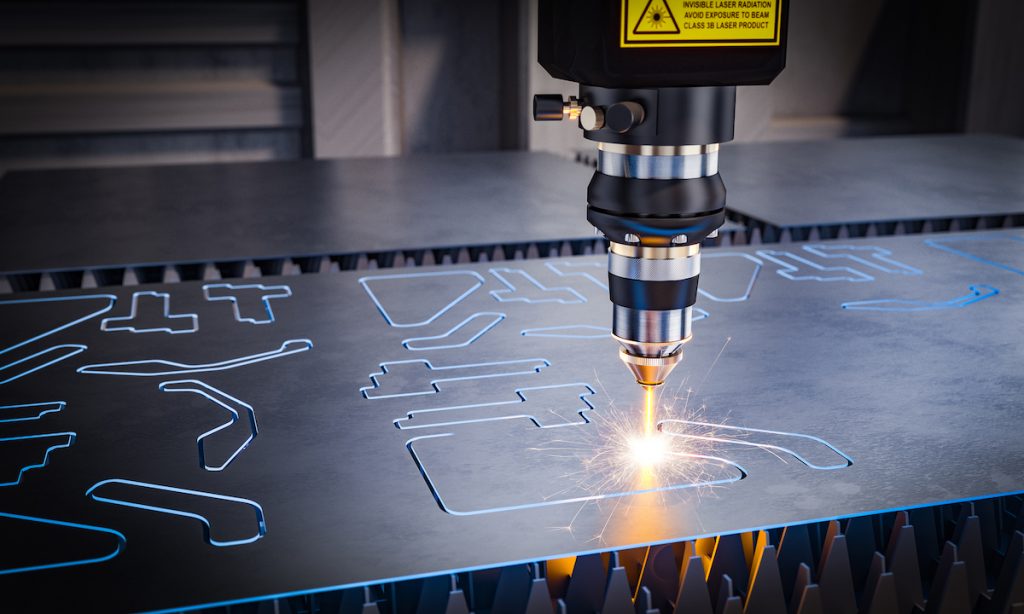

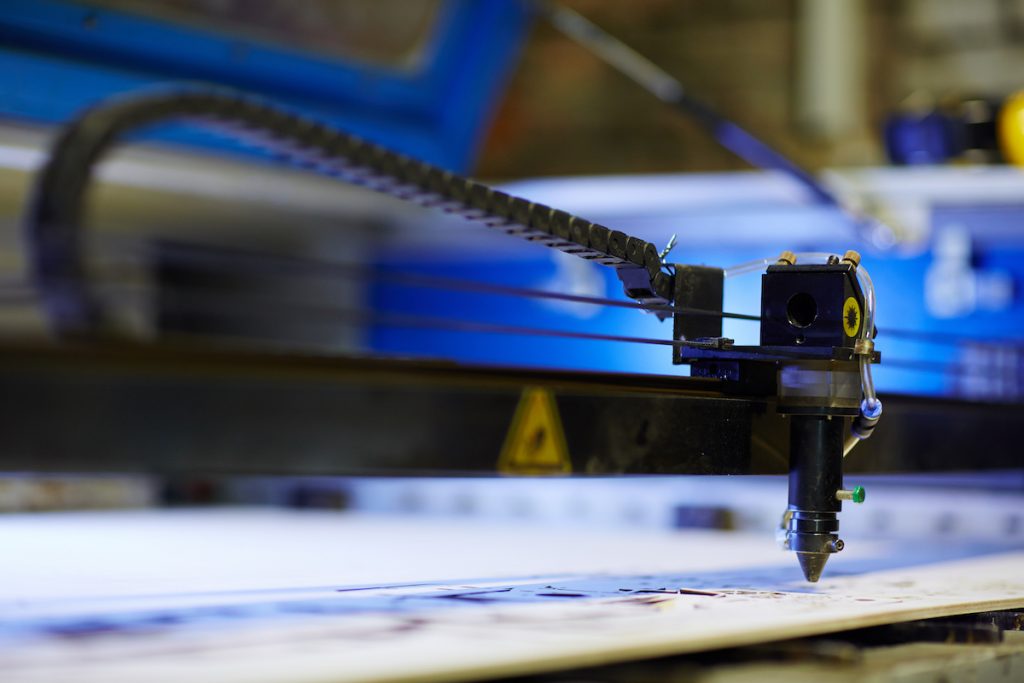

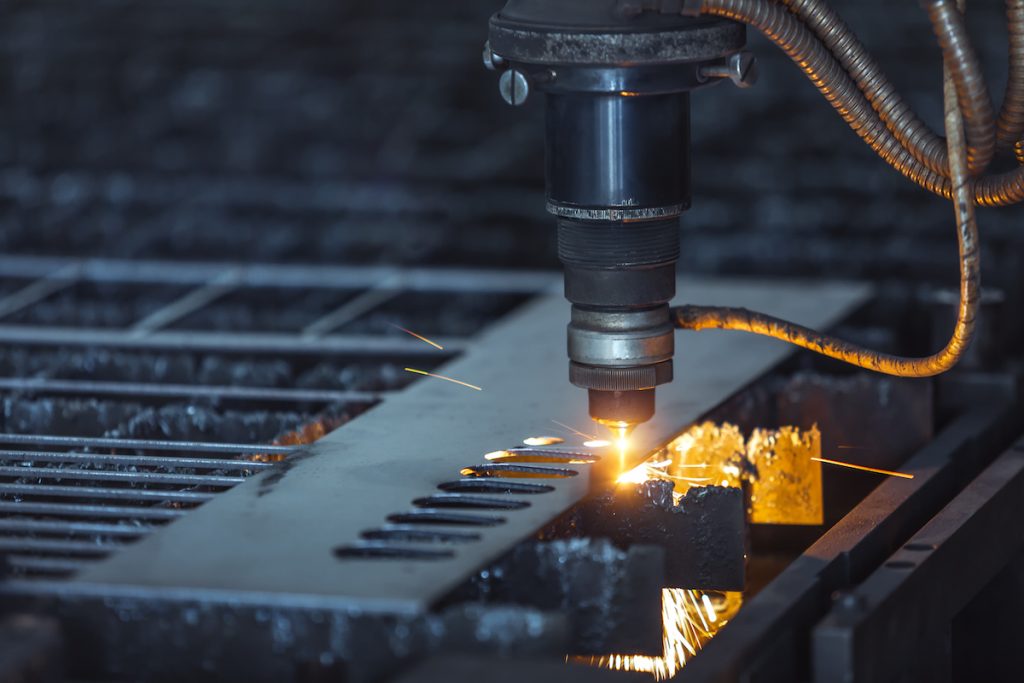

How to Reduce CNC Setups to Improve Uptime

Manufacturing companies always focus on downtime to improve processes and increase efficiency in a facility. There are many different categories of downtime, including downtime from jams, breakdowns, operator errors, and more. Machine setup is one area where downtime is manageable and predictable. It’s critical to efficient business processes and producing profitable parts with the least […]

Read more →