Walk any modern plant floor, and you’ll see the familiar pillars of industry: machines, materials, and people. But a new class of essential worker has emerged, one you cannot see. It doesn’t draw a salary, take a break, or retire. It is the industrial document, and its transformation from a passive record into an active, intelligent agent is the most underrated revolution in manufacturing today.

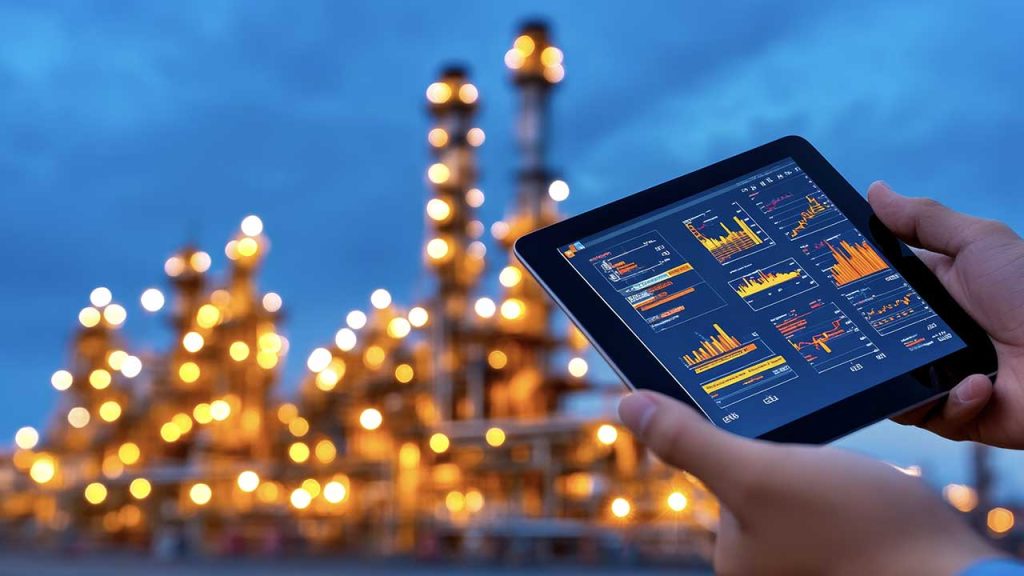

For decades, documents were the end of a process—a report to file, a certificate to store, a manual to gather dust. In the AI-driven factory, they are becoming the beginning. They are the critical data layer that turns raw sensor alarms into actionable intelligence. This isn’t about replacing the plant manager; it’s about arming them with a complete, contextualized picture they’ve never had before.

From Filing Cabinet to First Responder

Consider the alarm flood—a chronic problem that burns managerial bandwidth. As cited in real-world implementations, up to 80% of the data needed to triage these alarms is locked in unstructured documents. A high-temperature alert on a compressor is just noise. But when the system instantly cross-references that live sensor data with the compressor’s most recent maintenance log (a PDF), the specific lubrication spec (a scanned manual), and the technician’s handwritten notes from the last shutdown, the alert transforms. It becomes: “Alert: Compressor C-202. Bearing temperature threshold exceeded. Last serviced 88 days ago per log #442. Recommend inspection per Section 3.2 of the manual. Required oil: SynLube XG-7.”

The document has become a silent, instant colleague to the manager. It didn’t make the decision. It performed the seconds-long investigative work that would have taken a human 20 minutes, presenting a consolidated fact pattern for human judgment.

The Manager’s New Role: Orchestrator of Intelligence

This shifts the plant manager’s role from information hunter-gatherer to orchestrator of validated intelligence. The cognitive load of searching, cross-referencing, and validating data across disparate systems is automated. The manager’s authority is amplified, not diminished. They are now acting on prescriptive alerts backed by a clear, auditable digital paper trail—provenance that shows the source document, the extraction confidence, and the business rule that triggered the recommendation.

This is the practical, documented path to scaling AI: not by asking managers to trust a black-box model, but by showing them the source material. This is how you turn AI from a fascinating pilot into a trusted colleague. The goal is to make audits “non-events” because the evidence for every decision is pre-assembled and verifiable with a click.

The Realistic, Unseen Workforce

The factories pulling ahead are not those firing managers and hiring AI. They are the ones hiring systems to activate their archives. They are converting 50-year-old equipment manuals, handwritten shift logs, and supplier quality certificates into searchable, connective tissue for their operations. This documented knowledge, often walked out the door with retiring experts, is being reinstated as a permanent, queryable asset.

The triumph of the next-generation plant manager won’t be commanding robots. It will be their ability to command the full depth of their operation’s institutional knowledge in real-time. Their most vital team members will be the silent, digital workhorses they empowered—the decades of documentation, finally awake and working the shift alongside everyone else.

About the author

Lucian Fogoros is the Co-founder of IIoT World.