The race in CNC machining is no longer about who has the fastest spindle—it’s about who can validate reality before cutting metal.

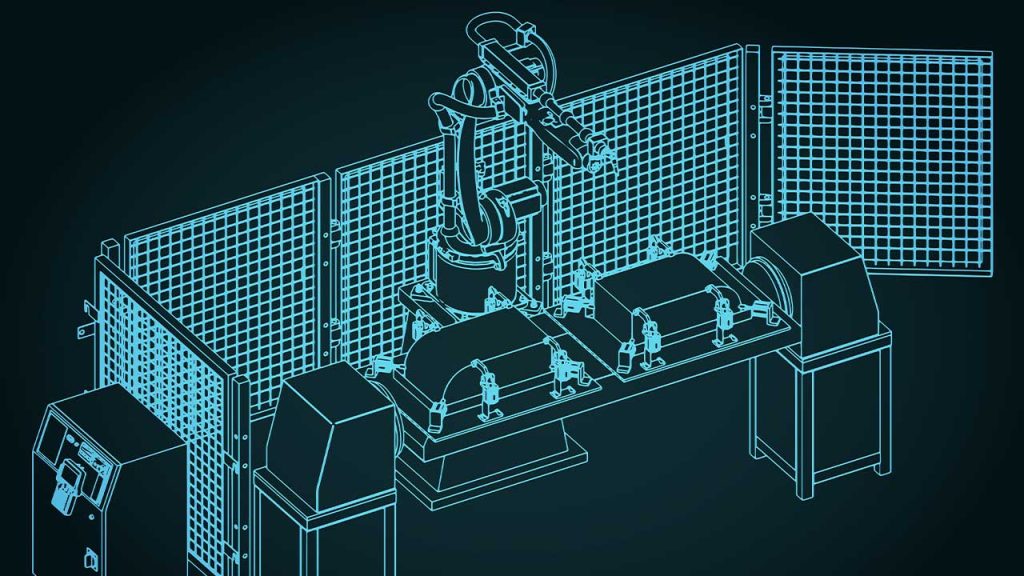

Across global manufacturing, digital twin technology is emerging as a quiet disruptor, letting engineers simulate machines, verify programs, and train workers in a zero-risk environment.

As Siemens’ Dave Morley explained during CXO Insights, digital twins are now the backbone of the next wave in precision manufacturing, closing the skills gap and enabling smarter, leaner, and faster production cycles.

Why Simulation Is Becoming the New Shop Floor

CNC operations face a double pressure: a shrinking workforce and growing demand for high-mix, low-volume precision parts. Traditional approaches—manual setup, real-machine testing—are too slow and too costly.

That’s why manufacturers are moving the first phase of production to the digital floor.

By building a one-to-one model of the machine—complete with kinematics, control logic, and tooling—engineers can run every program virtually, catching collisions and inefficiencies before they reach the spindle.

A crash in the virtual world costs nothing; a crash on the floor can wipe out a week’s margin.

When Bidding Becomes a Science, Not a Guess

Digital twins are also changing how manufacturers quote and win projects.

In one aerospace case, a supplier used a virtual replica of a new CNC machine to simulate a large turbine casting operation. Within hours, they had precise cycle times, tooling costs, and profit projections—enough to bid with confidence and undercut competitors.

They didn’t just promise capability; they showed the customer the entire machining process virtually.

That level of transparency is becoming a decisive edge in high-value manufacturing contracts.

Precision Engineering Meets Energy Intelligence

Modern CNC systems are integrating real-time analytics and adaptive control, giving digital twins a second life once machines go live.

Software now reads spindle torque in milliseconds and adjusts feed rates automatically—speeding up where possible, slowing down when tool wear increases.

The impact?

- Lower energy use per part

- Longer tool life

- Reduced scrap and rework

This feedback loop between virtual and physical performance links precision with sustainability—a metric OEMs and Tier 1s increasingly measure when awarding contracts.

For SMB Manufacturers: Start with One Digital Thread

Digitalization doesn’t mean tearing out existing systems.

For small and mid-size CNC shops, the smartest path is to pick one workflow—for instance, part-program validation or operator training—and virtualize that first.

Once the ROI is proven, expand to machine optimization, quoting, or predictive maintenance.

The key is not adopting every new tool, but building one digital thread that connects design, simulation, and production data.

As Dave Morley puts it, “Start small, but start. The cost of waiting is being priced out of the market.”

This article was written based on the video interview with Dave Morley, Sales Manager – Americas, Siemens Digital Industries.

Related articles: