Answering an AI Frontiers 2025 audience question

Context. During AI Frontiers 2025, an attendee asked: Who should be the business owner and senior stakeholder for an AI proof of concept—and how should it be structured for quick wins and long-term scale? This article distills the panel’s answer from “Building Data Accuracy and AI Trust in Smart Manufacturing.” Want to check the on-demand video? Watch here.

The short answer

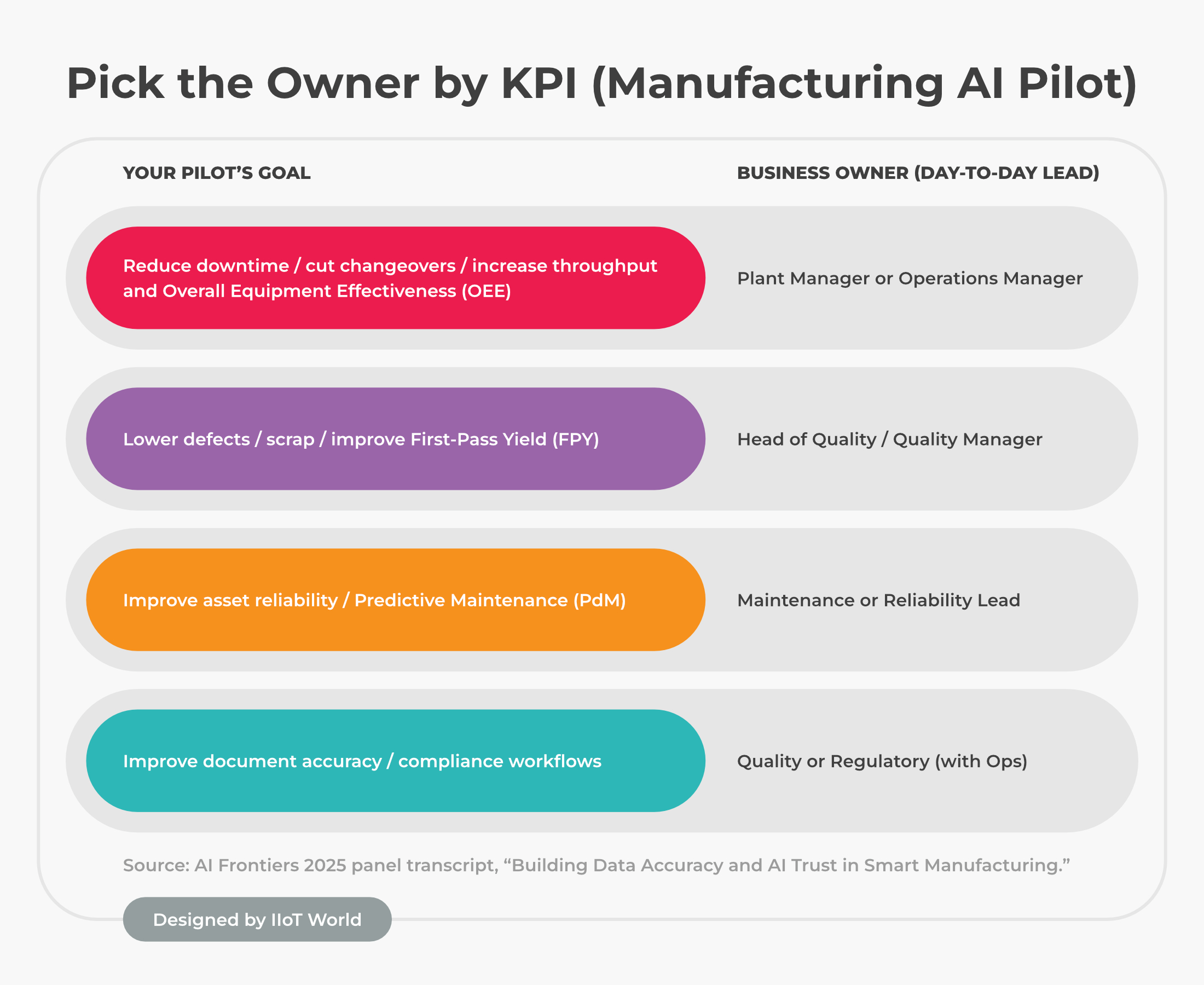

• Business owner: a line-of-business leader with Profit & Loss (P&L) accountability over the Key Performance Indicator (KPI) your pilot aims to move.

• Senior stakeholder (executive sponsor): the head of Operations (Ops)—for example, a VP/Director of Manufacturing—who can remove roadblocks and standardize what works across sites.

• Information Technology (IT) and Quality/Regulatory are core partners for data, integration, governance, and auditability—but not the owners.

Why this works: pilots fail when they’re IT-only or when success isn’t framed in plant outcomes. Ownership by the leader who owns the result (e.g., downtime, scrap, yield, changeovers) anchors the pilot to measurable value and speeds scale-up.

What the business owner does: define the problem and success metric (the KPI), provide process experts and data, make go/no-go decisions, and capture the benefits if it scales.

What the senior stakeholder does

Who: typically a VP/Director of Operations/Manufacturing (with the Chief Information Officer (CIO) or IT Director and the Head of Quality as close partners).

Role: secure budget and staffing, clear cross-functional blockers, and standardize a repeatable playbook for multi-site rollout (data standards, connectors, procedures, change management).

How to structure the pilot (simple, fast, measurable)

- Choose one plant problem that moves the P&L (e.g., “cut changeover minutes by 15%”).

- Baseline the KPI (last 60–90 days) with Ops and Finance.

- Use data you already trust; don’t prototype on random slices.

- 90-day runbook

- Weeks 1–2: secure data access; agree on the KPI/target; confirm safety and compliance.

- Weeks 3–6: deploy on a real line/asset with a human-in-the-loop validation step.

- Weeks 7–10: stabilize; watch leading indicators (exceptions go down, straight-through processing goes up).

- Weeks 11–12: confirm KPI lift with Finance; decide scale / no-scale.

- Document the playbook (data model and standards, connectors, governance, user experience, change management) for the next site.

Report results in plant language: downtime minutes, scrap rate, FPY, changeover minutes—not “models deployed.”

Where IT and compliance fit (critical partners)

- IT/Data: secure integrations to systems like the Manufacturing Execution System (MES), Computerized Maintenance Management System (CMMS), Product Lifecycle Management (PLM), and Electronic Document Management System (EDMS); enforce governance (ownership, lineage, role-based access); stand up monitoring and Machine Learning Operations (MLOps) for scale.

- Quality/Regulatory: build audit trail and traceability by design so the pilot is safe to scale across sites without rework.

Quick checklist

Do

- Put the line leader with P&L in charge.

- Start with data quality at the source and clear governance (ownership, lineage, access).

- Reuse a template (data model, connectors, onboarding checklist) so new sites onboard in weeks, not quarters.

Don’t

- Run it as an IT-only initiative.

- Build on messy, untrusted data.

- Treat compliance as an afterthought.

An AI Proof of Concept (PoC) should be owned by the business leader who owns the target KPI, backed by a senior operations sponsor, with IT and Quality as indispensable partners. That structure turns Artificial Intelligence (AI) from a science project into measurable plant results—and makes scaling across sites practical.

Source: AI Frontiers 2025 panel transcript, “Building Data Accuracy and AI Trust in Smart Manufacturing.”